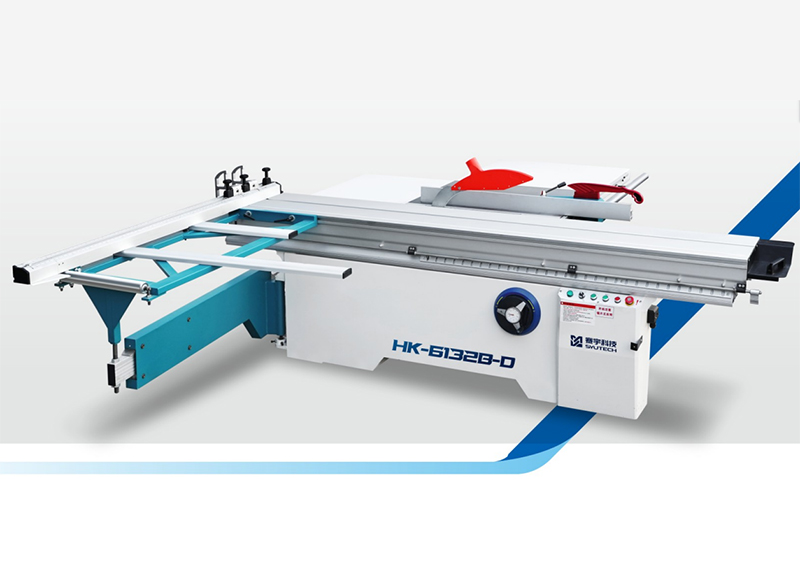

High-Quality Industrial Table Saw for Efficient Woodworking

By:Admin

An industrial table saw has been recalled by the manufacturer after it was discovered that the saw poses a safety hazard to users. The recall, which was announced by the Consumer Product Safety Commission, affects thousands of units of the saw that have been sold to woodworkers and construction professionals across the country.

The industrial table saw, which is produced by a well-known manufacturer of power tools and equipment, has been found to have a defect that could cause the saw to malfunction during use. Specifically, the saw's blade has been known to detach from the machine while in operation, posing a serious risk of injury to the user and those nearby.

The manufacturer, {company name}, has issued a statement regarding the recall, urging all owners of the affected saw to immediately stop using the machine and to contact the company for further instructions. In the statement, {company name} expressed regret for the inconvenience that the recall may cause, but emphasized that the safety of their customers is their top priority.

The recall of the industrial table saw is just the latest in a series of setbacks for {company name}, which has been struggling to maintain its reputation for quality and safety in recent years. The company, which has been a leader in the power tool industry for decades, has faced criticism over the safety of some of its products, leading to a number of high-profile recalls and lawsuits.

In response to these challenges, {company name} has pledged to redouble its efforts to ensure the safety and reliability of its products. The company has implemented new quality control measures and has invested in research and development to create innovative new safety features for its power tools.

Despite these efforts, the recall of the industrial table saw is a major blow to {company name}'s reputation, and it remains to be seen how the company will recover from this latest setback. Many in the industry are questioning whether {company name} will be able to regain the trust of its customers and repair the damage to its brand.

In the meantime, owners of the affected industrial table saw are urged to heed the manufacturer's warning and stop using the machine immediately. The potential risk of injury from the saw's defect is simply too great to ignore, and all precautions should be taken to ensure the safety of those who use {company name}'s products.

As the power tool industry continues to evolve, it is clear that safety must be a top priority for all manufacturers. The recall of the industrial table saw serves as a sobering reminder of the potential dangers that can arise from defective products, and it is incumbent upon companies like {company name} to do everything in their power to protect their customers from harm.

For now, the recall of the industrial table saw is a cautionary tale for consumers and businesses alike, and it underscores the need for rigorous safety standards and vigilant quality control in the power tool industry. Only time will tell whether {company name} can recover from this latest setback and rebuild the trust of its customers.

Company News & Blog

Efficient and Precision CNC Side Grooving Machines: Boost Your Productivity

[Company Name] Introduces Innovative CNC Side Grooving Machine for Enhanced Precision and Efficiency[CITY, DATE] - [Company Name], a leader in industrial automation and machinery, has recently unveiled their latest innovation in the field of CNC machinery, the cutting-edge side grooving machine. With this new addition to their product line, [Company Name] aims to revolutionize the manufacturing industry by providing a highly efficient, precise, and reliable solution for various grooving applications.The new CNC side grooving machine is a result of extensive research and development conducted by [Company Name]'s team of skilled engineers and experts in the field of industrial machinery. Designed to meet the increasing demand for precise side grooves in various materials such as metal, wood, plastic, and composite materials, this advanced machine offers unparalleled performance and flexibility.One of the key features of the CNC side grooving machine is its high level of precision. Equipped with state-of-the-art technology, including advanced servo motors and precision ball screws, it ensures that each side groove is perfectly dimensioned and accurately positioned. This level of precision not only improves the overall quality of the final product but also minimizes material wastage, leading to substantial cost savings for manufacturers.Moreover, the CNC side grooving machine boasts a user-friendly interface, making it easily operable even for those who are new to CNC machinery. The intuitive touchscreen display allows operators to easily program and control the machine, making adjustments and fine-tuning settings to achieve the desired grooving specifications effortlessly. Additionally, the machine's advanced software enables seamless integration with existing production lines, thus enhancing productivity and efficiency in manufacturing processes.Safety has been a key consideration in the design and development of this CNC side grooving machine. The machine is equipped with a range of safety features, including emergency stop buttons, protective covers, and sensors that detect any abnormalities or malfunctions. These safety measures ensure the well-being of operators and reduce the risk of accidents in the work environment, making it an ideal choice for companies prioritizing worker safety.The versatility of the CNC side grooving machine is another aspect that sets it apart from its competitors. With customizable options, manufacturers have the flexibility to adjust various parameters such as feed rate, cutting depth, and tooling selection according to their specific requirements. This adaptability makes it suitable for a wide range of applications, including grooving for automotive parts, aerospace components, furniture manufacturing, and architectural woodworking, to name just a few.In terms of productivity, the CNC side grooving machine delivers exceptional results. Its high-speed spindle and rapid tool change system optimize production cycles, ensuring fast and efficient operation. This allows manufacturers to meet tight deadlines and manage high-volume production demands efficiently. Moreover, the machine's robust construction and durable components contribute to its long service life, minimizing downtime for maintenance and repair.With the introduction of the innovative CNC side grooving machine, [Company Name] aims to continue providing cutting-edge solutions that empower manufacturers with enhanced efficiency and productivity. By combining advanced technology, precision engineering, and user-friendly design, this machine is set to become an essential tool for businesses striving for excellence in their manufacturing processes.About [Company Name]:[Company Name] is a globally renowned provider of industrial automation and machinery solutions. With a rich history spanning over [number] years, the company has consistently evolved to cater to the dynamic needs of the manufacturing sector. Whether it is CNC machinery, robotic systems, or other industrial automation equipment, [Company Name] prides itself on delivering innovative and reliable solutions that enable businesses to thrive in today's competitive market.For more information about the CNC side grooving machine and other products offered by [Company Name], please visit [company website].Contact:[Company Name][Contact Person][Title][Phone number][Email address]

Top 10 Benchtop Bandsaws for Your Woodworking Projects

In the world of woodworking and metalworking, a benchtop bandsaw is an essential tool for precision cutting and shaping. This powerful and versatile machine is a popular choice for both amateur and professional craftspeople, and it has earned a reputation for its reliability and efficiency.{Company} is one of the leading manufacturers of benchtop bandsaws, and they have been producing high-quality tools for over 50 years. Their commitment to innovation and customer satisfaction has made them a trusted name in the industry, and their bandsaws are known for their durability and precision.The benchtop bandsaw from {Company} is designed for easy operation and maintenance, with user-friendly features that make it suitable for both beginners and experienced craftsmen. Its compact size and portability make it a convenient choice for small workshops or on-site projects, and its cutting accuracy and power make it a valuable addition to any workspace.One of the standout features of the {Company} benchtop bandsaw is its powerful motor, which delivers a smooth and consistent cutting performance. Whether slicing through hardwood, metal, or plastic, this bandsaw provides the precision and control needed to achieve clean and accurate cuts every time. Its adjustable blade speed and tension control further enhance its cutting capabilities, allowing users to tackle a wide range of materials and cutting tasks with ease.Safety is also a top priority for {Company}, and their benchtop bandsaw is equipped with safety features to protect users during operation. From the blade guard and emergency stop button to the well-designed table and blade tracking system, every aspect of this bandsaw is engineered to keep users safe while they work.In addition to its performance and safety features, the {Company} benchtop bandsaw is also designed for convenience and ease of use. Its intuitive design and simple controls make it a user-friendly choice for craftsmen of all skill levels, and its ergonomic features ensure a comfortable and efficient cutting experience. From the quick-release blade tension to the tilting table and dust port, every detail of this bandsaw is crafted with the user in mind.To further enhance its versatility, the {Company} benchtop bandsaw is compatible with a range of accessories and attachments. Whether it's a miter gauge, rip fence, or a specialized blade, users can customize their bandsaw to suit their specific cutting needs and preferences. This adaptability makes the {Company} benchtop bandsaw a valuable tool for a wide variety of projects and applications.Beyond its impressive performance and features, {Company} takes pride in providing excellent customer service and support. They offer comprehensive product warranties and technical assistance to ensure that their customers have a positive experience with their bandsaws. This commitment to customer satisfaction has earned {Company} a loyal customer base and a reputation for reliability and integrity in the industry.In conclusion, the benchtop bandsaw from {Company} is a top choice for craftsmen seeking a powerful, reliable, and user-friendly cutting tool. With its precision cutting capabilities, safety features, and convenient design, this bandsaw is a valuable addition to any woodworking or metalworking workshop. Backed by {Company}'s decades of experience and commitment to excellence, this benchtop bandsaw is a tool that craftsmen can rely on for years to come.

New Advances in Wood Trimmer Technology: Enhancing Efficiency and Precision

Title: Revolutionizing Woodworking: A Game-Changing Wood Trimmer Set to Disrupt the MarketIntroduction:In today's fast-paced world, with consumers seeking convenience and efficiency, the woodworking industry has been presented with a groundbreaking solution: the brand new wood trimmer. Developed by an innovative company, the wood trimmer aims to revolutionize traditional woodworking techniques, making them faster, more accurate, and user-friendly. With its cutting-edge features and state-of-the-art technology, this wood trimmer is poised to disrupt the market and transform the way craftsmen and woodworking enthusiasts work.1. Background and Market Analysis:Woodworking has evolved significantly over the years, with the demand for precision and efficiency constantly driving the development of new tools and techniques. Traditional woodworking tasks often require manual accuracy, attention to detail, and time-consuming processes. However, with the introduction of the wood trimmer, these challenges are set to be alleviated. Market analysis reveals a growing demand for advanced woodworking tools that can accelerate project completion while ensuring impeccable precision.2. Introducing the Game-Changing Wood Trimmer:Awe-inspiring in both design and functionality, the wood trimmer eliminates the struggles associated with traditional woodworking tools. Manufactured by an expert team of engineers and designers, this cutting-edge tool offers a seamless and efficient user experience, allowing both professionals and hobbyists to unlock their woodworking potential.Equipped with advanced features, the wood trimmer boasts unprecedented precision. Utilizing high-speed motor technology, this versatile device can smoothly maneuver through various wood types, including hardwood, softwood, plywood, and even plastic materials. Its exceptional cutting capabilities ensure clean and smooth edges, reducing the need for meticulous sanding or buffing.3. Key Features and Benefits:a) Enhanced Safety Measures: The wood trimmer is equipped with a safeguard mechanism that prevents accidental starts. Users can confidently handle the tool without worrying about accidental injuries, ensuring their peace of mind throughout the woodworking process.b) Adjustable Cutting Depth: The wood trimmer offers flexibility, with an adjustable cutting depth feature that allows users to customize their cuts according to specific project requirements. This empowers woodworking professionals to work on diverse applications while maintaining absolute precision.c) Ergonomic Design: The wood trimmer's ergonomic design ensures extended periods of comfortable and fatigue-free usage, allowing users to focus on their craftsmanship without distractions. With its lightweight construction, maneuverability is optimized, making it an ideal tool for intricate woodworking projects.d) Dust Collection System: Recognizing the need for a clean and dust-free workspace, the wood trimmer is equipped with an integrated dust collection system. This feature ensures minimal dust accumulation, preserving the health of both the user and the surrounding environment.4. Industry Impact and Reviews:Since its launch, the wood trimmer has garnered significant attention and positive reviews from woodworking experts, industry professionals, and enthusiasts alike. Renowned craftsmen have applauded its precision, ease of use, and noticeable reduction in working time. Woodworkers claim that the wood trimmer has transformed their workflow, enabling them to tackle complex projects more efficiently.5. Future Possibilities:The wood trimmer is just the beginning of the company's commitment to pushing the boundaries of woodworking technology. Their innovative research and development team continues to explore ways to enhance the performance, features, and versatility of their tools. With the wood trimmer leading the way, the company aims to establish itself as a pioneer in the woodworking industry, inspiring professionals and hobbyists alike.Conclusion:As consumers increasingly demand efficiency, precision, and convenience, the introduction of the wood trimmer promises to revolutionize the woodworking industry. With its exceptional features, enhanced safety measures, and ergonomic design, this game-changing tool enables craftsmen to sharpen their skills and enhance their woodworking capabilities. As testimonials pour in and professionals acknowledge its prowess, the wood trimmer has unquestionably solidified its position as an industry game-changer, paving the way for a new era of woodworking excellence.

Top benchtop bandsaw for woodworking and metal cutting

The Benchtop Bandsaw is a versatile and powerful tool that is a must-have for any woodworking enthusiast or professional. With its compact design and high-performance capabilities, this bandsaw has quickly become a favorite among craftsmen and hobbyists alike.The Benchtop Bandsaw is perfect for cutting intricate curves and shapes in wood, metal, plastic, and other materials. Its precision blade and adjustable cutting speed make it easy to achieve professional-quality results with minimal effort. Additionally, the bandsaw's compact size allows for easy storage and transportation, making it a convenient addition to any workshop or job site.One of the key features of the Benchtop Bandsaw is its powerful motor, which provides ample cutting power for a wide range of materials. Whether you're working with hardwood, metal, or plastic, this bandsaw can handle the job with ease. Its adjustable cutting speed also allows for precise control over the cutting process, ensuring clean and accurate results every time.In addition to its performance capabilities, the Benchtop Bandsaw is also designed with user convenience in mind. Its easy-to-use controls and adjustable blade guard make it simple to operate, even for beginners. The bandsaw also features a sturdy construction and durable components, ensuring reliable performance and long-term durability.One of the company that is known for producing high-quality bandsaws is {}. With years of experience in the industry, {} has established itself as a leading manufacturer of woodworking and metalworking machinery. The company is dedicated to producing innovative and reliable tools that meet the needs of professionals and hobbyists alike.{} prides itself on its commitment to quality and customer satisfaction. Each bandsaw is built to the highest standards of craftsmanship and undergoes rigorous testing to ensure optimal performance. The company also offers comprehensive customer support and service, providing assistance with setup, maintenance, and troubleshooting for all of its products.Furthermore, {} is dedicated to continuous innovation and improvement. The company invests in research and development to stay ahead of the curve in the industry, constantly refining its products to meet the evolving needs of its customers. This commitment to innovation has made {} a trusted name in the woodworking and metalworking community.The Benchtop Bandsaw is a prime example of {}'s dedication to excellence. Its superior performance, user-friendly design, and durable construction make it a top choice for craftsmen and professionals around the world. With the backing of {}'s reputation for quality and reliability, the Benchtop Bandsaw is a tool that users can trust for all their cutting needs.In conclusion, the Benchtop Bandsaw is a standout tool in the woodworking and metalworking industry. Its powerful performance, user-friendly design, and reliable construction make it a valuable addition to any workshop or job site. With the backing of {}, users can trust that the Benchtop Bandsaw will deliver the results they need for years to come.

Expert Woodworking Tips for High-Quality Results

Moulder Woodworking is a renowned woodworking company that has been providing high-quality woodworking solutions for over two decades. The company specializes in producing a wide range of woodworking products, including furniture, cabinets, and other custom woodwork solutions for both residential and commercial clients. With a team of highly skilled and experienced craftsmen, Moulder Woodworking has established itself as a leader in the woodworking industry, known for its precision, attention to detail, and commitment to delivering exceptional customer satisfaction.The company's state-of-the-art facility is equipped with the latest woodworking technology, allowing them to produce top-quality products with efficiency and accuracy. From design and prototyping to manufacturing and finishing, Moulder Woodworking has the capability to handle every aspect of the woodworking process in-house, ensuring seamless production and timely delivery of products. Moreover, the company is committed to using sustainable and ethically sourced materials in their production processes, reflecting their dedication to environmental responsibility.Moulder Woodworking's dedication to quality and innovation has earned them a stellar reputation in the industry, and they have successfully completed numerous projects for a diverse clientele, including homeowners, interior designers, architects, and businesses. Their portfolio showcases a wide range of woodworking projects, from modern and minimalist designs to intricate and ornate pieces, demonstrating their versatility and ability to cater to various styles and preferences.In addition to their commitment to exceptional craftsmanship, Moulder Woodworking also places a strong emphasis on customer service. The company prides itself on its collaborative approach, working closely with clients to understand their specific needs, preferences, and vision. This client-centric approach allows them to create bespoke woodworking solutions that exceed expectations and bring their clients' ideas to life.Furthermore, Moulder Woodworking is dedicated to staying ahead of industry trends and advancements. The company actively invests in research and development, constantly exploring new techniques, materials, and technologies to enhance their capabilities and offer innovative solutions to their clients. This commitment to innovation and continuous improvement has positioned Moulder Woodworking as a forward-thinking and progressive leader in the woodworking sector.As part of their ongoing commitment to excellence, Moulder Woodworking recently announced a strategic partnership with a leading woodworking technology company to further enhance their production capabilities. This collaboration will see the implementation of state-of-the-art woodworking machinery and software, allowing Moulder Woodworking to streamline their processes, improve efficiency, and maintain their high standards of quality.The partnership will also enable Moulder Woodworking to expand their product offerings and take on more complex and ambitious projects, catering to the evolving needs of their clients. By leveraging the latest woodworking technology, the company aims to push the boundaries of woodworking craftsmanship and deliver even more exceptional products that showcase their expertise and creativity."We are thrilled to enter into this partnership, as it signifies our dedication to continuous improvement and our commitment to delivering the best possible woodworking solutions to our clients," stated the CEO of Moulder Woodworking. "By integrating advanced woodworking technology into our operations, we are confident that we will be able to elevate our capabilities and exceed the expectations of our clients, solidifying our position as a leader in the woodworking industry."With this strategic partnership in place, Moulder Woodworking is poised to embark on a new chapter of growth and innovation. The company's unwavering dedication to craftsmanship, customer satisfaction, and technological advancement ensures that they will continue to be at the forefront of the woodworking industry, delivering exceptional products and setting new standards of excellence. Through this collaboration, Moulder Woodworking is not only enhancing their own capabilities but also raising the bar for woodworking craftsmanship in the industry.

High-Powered Circular Saw Machine for Precision Wood Cutting

Circular Saw Machine For Wood Cutting - A Game Changer in the Woodworking IndustryThe woodworking industry is constantly evolving, with technological advancements and innovations revolutionizing the way wood is cut, shaped, and crafted. One such innovation that is making waves in the industry is the Circular Saw Machine for Wood Cutting, developed and manufactured by a leading company in the woodworking machinery sector.This state-of-the-art Circular Saw Machine is designed to meet the diverse cutting needs of woodworking professionals, from carpenters and furniture makers to construction contractors and DIY enthusiasts. Equipped with precision engineering and cutting-edge technology, this machine is set to be a game changer in the woodworking industry.The machine features a powerful circular saw blade that is capable of cutting through various types of wood with unmatched speed and accuracy. Whether it's hardwood, softwood, plywood, or engineered wood, this machine delivers clean and precise cuts, making it an indispensable tool for woodworkers.One of the key features of this Circular Saw Machine is its advanced dust extraction system, which effectively removes sawdust and debris during the cutting process. This not only ensures a cleaner and safer working environment but also prolongs the life of the machine and reduces maintenance requirements.In addition to its cutting prowess, the machine is also designed with user convenience in mind. With intuitive controls and ergonomic design, woodworkers can operate the machine with ease, leading to increased productivity and efficiency in their woodworking projects.Furthermore, safety is a top priority with this Circular Saw Machine, as it is equipped with advanced safety features to protect users from potential hazards. From blade guards to emergency stop mechanisms, the machine is engineered to provide a secure and worry-free cutting experience.The company behind this innovative Circular Saw Machine has a long-standing reputation for excellence in the woodworking machinery industry. With a commitment to quality, reliability, and customer satisfaction, the company has established itself as a trusted name among woodworking professionals and enthusiasts.In addition to manufacturing cutting-edge machinery, the company also offers comprehensive support and after-sales service, ensuring that their customers can maximize the capabilities of their machines and achieve optimal results in their woodworking endeavors.Furthermore, the company's dedication to innovation and continuous improvement is evidenced by their investment in research and development, allowing them to stay ahead of the curve and introduce cutting-edge solutions that cater to the evolving needs of the woodworking industry."We are proud to introduce our latest Circular Saw Machine for Wood Cutting, which embodies our commitment to delivering high-quality, reliable, and innovative machinery to the woodworking industry," said a spokesperson for the company. "We believe that this machine will empower woodworkers to take their craft to the next level, and we are excited to see the positive impact it will have on the woodworking community."As the woodworking industry continues to evolve, innovative solutions like the Circular Saw Machine for Wood Cutting are poised to redefine the way wood is cut and shaped. With its precision, power, and user-friendly design, this machine is set to become a staple in workshops and construction sites, empowering woodworkers to unleash their creativity and craftsmanship.In conclusion, the Circular Saw Machine for Wood Cutting represents a significant leap forward in woodworking technology, and with the backing of a reputable and customer-focused company, it is poised to make a lasting impact in the woodworking industry. Woodworkers and industry professionals can now look forward to a new era of cutting precision and efficiency, thanks to this game-changing machine.

High-precision CNC machining center for advanced manufacturing

CNC Machining Center Revolutionizing Manufacturing IndustryIn today's competitive manufacturing industry, precision, efficiency, and flexibility are key factors in staying ahead of the competition. This is where CNC machining centers have played a crucial role in revolutionizing the manufacturing process. With the advancements in technology and the introduction of innovative CNC machining centers, manufacturers are now able to achieve unprecedented levels of accuracy, speed, and productivity.One company at the forefront of this revolution is {}. With a history of excellence and innovation in the field of manufacturing, {} has been a leading provider of cutting-edge CNC machining centers that have redefined the industry standards.The latest CNC machining center from {} is a game-changer in the industry. Featuring state-of-the-art technology and advanced capabilities, this machining center is designed to meet the most demanding production requirements. With its high-speed spindle, precise positioning, and multi-axis control, it is capable of producing complex and intricate parts with unparalleled accuracy and repeatability.One of the key features of this CNC machining center is its flexibility. Thanks to its advanced programming and control systems, it can easily switch between different tasks and adapt to new production requirements without the need for extensive retooling or setup. This level of flexibility is a game-changer for manufacturers, as it allows for quick and efficient changeovers, resulting in reduced downtime and increased productivity.In addition to its cutting-edge technology and flexibility, this CNC machining center is also designed with the operator in mind. With its user-friendly interface and intuitive controls, it allows operators to easily program, monitor, and adjust the machining process, ensuring optimal performance and efficiency.The impact of this CNC machining center on the manufacturing industry is profound. By enabling manufacturers to produce high-quality parts with unmatched precision and speed, it has raised the bar for the entire industry. Whether it's automotive components, aerospace parts, medical devices, or any other precision parts, this machining center has proven to be a game-changer for manufacturers across various sectors.Furthermore, the implementation of this CNC machining center has also resulted in significant cost savings for manufacturers. Its high-speed machining capabilities and advanced tool management systems have reduced production cycle times, leading to lower production costs and improved overall profitability.In addition to its technical capabilities, {} provides comprehensive training and support to ensure that manufacturers can fully harness the potential of this CNC machining center. This includes training programs for operators, as well as ongoing technical support and maintenance services to keep the machining center running at peak performance.As a result, manufacturers who have implemented these CNC machining centers have seen a significant improvement in their overall production capabilities, which has ultimately translated into a competitive advantage in the market.Looking ahead, {} is committed to further advancing the capabilities of CNC machining centers and pushing the boundaries of manufacturing technology. With a relentless focus on innovation and a deep understanding of the evolving needs of the industry, {} is poised to continue leading the way in revolutionizing the manufacturing industry.In conclusion, the introduction of advanced CNC machining centers, such as the one offered by {}, has redefined the manufacturing industry. With its cutting-edge technology, flexibility, and cost-saving benefits, it has enabled manufacturers to achieve unprecedented levels of precision, efficiency, and productivity. As the industry continues to evolve, {} is at the forefront, driving the innovation that will shape the future of manufacturing.

Ultimate Guide to Choosing the Best Router Machine for Your Needs

Today, we are excited to announce the launch of a new router machine by our company, a leading provider of innovative and cutting-edge manufacturing equipment. This new router machine is set to revolutionize the manufacturing industry with its advanced technology and increased efficiency.The new router machine, which will be called the R-800, is designed to meet the growing demand for high-speed and precise routing in various industries such as woodworking, metalworking, and plastic fabrication. With its state-of-the-art features and user-friendly interface, the R-800 is set to become a game-changer in the field of CNC routing.One of the key highlights of the R-800 is its cutting-edge spindle technology, which enables it to achieve unprecedented levels of speed and accuracy in routing operations. This means that manufacturers can now produce complex and intricate designs with ease, leading to a significant improvement in the overall quality of their products.In addition to its advanced spindle technology, the R-800 also comes equipped with a high-performance control system, which allows for seamless integration with CAD/CAM software. This means that users can easily import their designs and execute them with precision, reducing the margin for error and increasing the overall efficiency of the manufacturing process.Furthermore, the R-800 features a robust and durable construction, ensuring that it can withstand the rigors of heavy-duty industrial use. This means that manufacturers can rely on the R-800 to deliver consistent and reliable performance, even in the most demanding production environments.As a company, we are committed to providing our customers with the latest technologies and solutions to help them stay ahead of the competition. With the launch of the R-800, we are proud to offer our clients a cutting-edge router machine that is designed to meet the evolving needs of the manufacturing industry.The R-800 is the result of extensive research and development, and we are confident that it will set a new standard for CNC routing technology. By incorporating feedback from industry professionals and leveraging our expertise in manufacturing equipment, we have been able to create a router machine that not only meets but exceeds the expectations of our customers.Beyond its impressive technical specifications, the R-800 is also backed by our industry-leading customer support and service. With a team of dedicated professionals who are committed to ensuring the success of our clients, we are confident that the R-800 will deliver exceptional value and performance for years to come.In conclusion, the launch of the R-800 marks a significant milestone for our company and the manufacturing industry as a whole. With its advanced technology, precision engineering, and exceptional performance, the R-800 is set to propel the industry forward and empower manufacturers to achieve new heights of productivity and innovation.We are excited to introduce the R-800 to the market and look forward to seeing the positive impact it will have on the manufacturing industry. As we continue to push the boundaries of what is possible in manufacturing equipment, we remain committed to delivering solutions that empower our customers and drive the industry forward.

Efficient Cabinet Hole Drilling Machine for Home Improvement Projects

The industrial sector has always been at the forefront of innovation and development, constantly striving to improve productivity and efficiency. In line with this, a new cabinet hole drilling machine has been introduced by a leading company in the manufacturing industry. With a focus on precision, speed, and reliability, this cutting-edge machine is set to revolutionize the way cabinet holes are drilled in production processes.As a company that has been at the forefront of the manufacturing industry for over two decades, our commitment to delivering high-quality, state-of-the-art machinery has always been unwavering. Our latest offering, the cabinet hole drilling machine, is a testament to our dedication to innovation and excellence. Equipped with advanced technology and robust construction, this machine is designed to meet the needs of modern manufacturing operations.The cabinet hole drilling machine is designed to streamline the process of drilling holes in cabinets, ensuring accuracy and efficiency. With its high-speed drilling capabilities and precise positioning, it is able to deliver consistent and accurate results, significantly reducing production time and minimizing errors. This not only enhances productivity but also ensures the quality of the end product, meeting the high standards of the industry.One of the key features of the cabinet hole drilling machine is its versatility. It is capable of drilling a wide range of hole sizes and patterns, allowing for customization and flexibility in production. This adaptability makes it suitable for various applications within the manufacturing sector, catering to the diverse needs of different industries. Whether it is for kitchen cabinets, office furniture, or storage units, this machine offers the agility to meet the specific requirements of each project.Furthermore, the cabinet hole drilling machine is designed with user convenience in mind. Its intuitive interface and user-friendly controls make it easy to operate, reducing the need for extensive training and minimizing the risk of human errors. Additionally, its durable construction and low maintenance requirements contribute to its cost-effectiveness, ensuring long-term reliability and performance.In line with our commitment to sustainable and environmentally friendly practices, the cabinet hole drilling machine is designed to optimize energy efficiency and minimize waste. By utilizing advanced technologies, it is able to operate with minimal energy consumption while maximizing productivity. This not only reduces the carbon footprint of manufacturing operations but also contributes to cost savings for businesses.The introduction of the cabinet hole drilling machine is a testament to our ongoing dedication to pushing the boundaries of what is possible in the manufacturing industry. We believe that through innovation and technological advancement, we can continue to drive progress and empower businesses to achieve their goals.Looking ahead, we are committed to furthering our research and development efforts to bring even more cutting-edge solutions to the market. We are confident that the cabinet hole drilling machine will set a new standard for precision and efficiency in cabinet production, and we are excited to see the impact it will have on the industry.In conclusion, the cabinet hole drilling machine represents a significant advancement in the manufacturing sector, offering unparalleled precision, speed, and reliability. With its versatility and user-friendly design, it has the potential to transform production processes and drive productivity for businesses across the board. As a company dedicated to innovation and excellence, we are proud to bring this breakthrough technology to the market and look forward to the positive impact it will have on the industry.

Innovative Autonomous Robotic Cutting Tool: The Future of Construction and Demolition

Rip Saw, a leading manufacturer of cutting-edge industrial equipment, has been making waves in the manufacturing industry with their innovative and efficient machinery. With over 30 years of experience in the manufacturing and design of industrial equipment, Rip Saw has established itself as a trusted and reliable source for high-quality machinery.The company prides itself on its commitment to providing reliable and durable equipment that is designed to meet the specific needs of its customers. Rip Saw's dedication to quality and innovation has earned them a reputation for excellence in the industry.One of Rip Saw's most popular products is their line of cutting-edge industrial saws, which are designed to provide precision and efficiency in a variety of manufacturing applications. Whether it's cutting wood, metal, or other materials, Rip Saw's saws are engineered to deliver unmatched performance and reliability.In addition to their saws, Rip Saw also offers a wide range of complementary equipment and accessories, including dust collection systems, automation solutions, and more. This comprehensive approach to manufacturing equipment allows Rip Saw to provide complete solutions to their customers, helping them to optimize their production processes and achieve better results.One of the key factors that sets Rip Saw apart from their competitors is their dedication to innovation and continuous improvement. The company invests heavily in research and development to ensure that their products are always at the forefront of technological advancements. By staying ahead of the curve, Rip Saw is able to offer their customers the latest and most advanced equipment on the market.Furthermore, Rip Saw is committed to providing exceptional customer service and support. Their team of knowledgeable and experienced professionals are always available to assist customers with any questions or concerns they may have. This commitment to customer satisfaction has helped Rip Saw to build long-term relationships with many of their clients, who continue to rely on the company for all their manufacturing equipment needs.In recent news, Rip Saw has announced the launch of a new line of industrial saws that are set to revolutionize the industry. These new saws feature state-of-the-art technology and enhanced capabilities, allowing for even greater precision and efficiency in manufacturing processes. With the introduction of these new products, Rip Saw is solidifying their position as a leader in the industry and raising the bar for what customers can expect from industrial equipment."We are thrilled to introduce our latest line of industrial saws to the market," said the CEO of Rip Saw. "These new saws represent the culmination of years of research and development, and we believe they will set a new standard for performance and reliability in the industry. We are confident that our customers will be impressed with the capabilities of these new saws and the impact they will have on their manufacturing operations."The new line of industrial saws from Rip Saw is expected to be available for purchase in the coming months and is already generating significant interest from manufacturers across the country. With their track record of excellence and commitment to innovation, Rip Saw is poised to continue leading the way in the manufacturing industry for years to come.As the industry continues to evolve, Rip Saw remains dedicated to providing cutting-edge solutions to meet the changing needs of their customers. With their unwavering commitment to quality, innovation, and customer satisfaction, Rip Saw is well-positioned to continue setting the standard for industrial equipment and solidifying their reputation as a trusted and reliable partner for manufacturers around the world.