Top Tips for Using Abs Edge Banding in Woodworking Projects

By:Admin

Abs Edge Banding, also known as acrylic edge banding, is a popular material used in the furniture industry for finishing the edges of various furniture pieces. It provides a smooth, durable and decorative finish to the edges of furniture, making it a preferred choice for both residential and commercial applications.

One of the leading suppliers of Abs Edge Banding is {Company Name}. With years of experience in the industry, {Company Name} has established itself as a reliable and trusted provider of high-quality edge banding solutions to furniture manufacturers, interior designers, and construction professionals.

{Company Name} offers a wide range of Abs Edge Banding products, including solid colors, wood grain patterns, metallic finishes, and custom color matching options. The company prides itself on its ability to meet the diverse needs and preferences of its customers, providing them with endless possibilities to enhance the aesthetic appeal of their furniture designs.

In addition to its extensive product range, {Company Name} is known for its commitment to quality and innovation. The company uses state-of-the-art manufacturing techniques and quality control processes to ensure that its Abs Edge Banding products meet the highest standards of quality and performance. Furthermore, {Company Name} continuously invests in research and development to stay ahead of market trends and technological advancements, offering its customers cutting-edge edge banding solutions that meet the evolving demands of the industry.

{Company Name} has also built a strong reputation for its exceptional customer service and support. Its team of knowledgeable and experienced professionals is dedicated to providing personalized assistance to customers, guiding them through the selection process, offering technical advice, and delivering efficient solutions to their edge banding needs. The company takes pride in its ability to form long-lasting partnerships with its customers, understanding their unique requirements and delivering tailored solutions that exceed their expectations.

Moreover, {Company Name} is committed to sustainability and environmental responsibility. The company sources materials from reputable suppliers and adheres to strict environmental regulations and standards in its manufacturing processes. {Company Name} is also focused on reducing its carbon footprint and minimizing waste, demonstrating its commitment to preserving the environment for future generations.

With its unwavering dedication to quality, innovation, customer service, and sustainability, {Company Name} has earned the trust and loyalty of a wide customer base, establishing itself as a leading provider of Abs Edge Banding solutions in the market. As the furniture industry continues to evolve and demand for high-quality edge banding products grows, {Company Name} remains at the forefront, setting new benchmarks for excellence and pushing the boundaries of what is possible in the world of edge banding.

In conclusion, {Company Name} is a company that is synonymous with excellence in the Abs Edge Banding industry. With its diverse product range, commitment to quality and innovation, exceptional customer service, and dedication to sustainability, the company has established itself as a trusted partner for furniture manufacturers, interior designers, and construction professionals seeking top-notch edge banding solutions. As the industry continues to evolve, {Company Name} is well-positioned to lead the way, setting new standards and delivering cutting-edge products and services that exceed customer expectations.

Company News & Blog

Revolutionize Your Woodworking with a CNC Wood Carving Machine

The demand for precision and efficiency in wood carving has been steadily increasing in the woodworking industry. Companies are always seeking innovative solutions to enhance their production processes and deliver high-quality products to their customers. Amidst this growing demand, a new player has emerged in the market with a groundbreaking solution – the CNC wood carving machine.This cutting-edge technology has caught the attention of woodworking professionals and enthusiasts alike, offering a new level of precision and automation in wood carving. The CNC wood carving machine, developed by an industry-leading company, is revolutionizing the way wood products are manufactured.Using state-of-the-art software and advanced robotics, the CNC wood carving machine is capable of creating intricate designs and patterns on wood with unparalleled accuracy. Its automated system eliminates the need for manual intervention, resulting in faster production and reduced margin for error. This not only increases productivity but also ensures consistent quality in every piece of carved wood.One of the key features of the CNC wood carving machine is its versatility. It can be used for a wide range of applications, from creating intricate designs on furniture and decorative panels to engraving personalized patterns on wooden products. This flexibility has made it a popular choice for woodworking companies looking to diversify their product offerings and meet the evolving demands of the market.The company behind the development of the CNC wood carving machine has a rich history in the woodworking industry. With decades of experience and expertise in manufacturing precision machinery, they have leveraged their knowledge to create a product that sets new standards in wood carving. Their commitment to innovation and continuous improvement has positioned them as a leader in the industry, earning the trust and confidence of their customers.In addition to its innovative technology, the CNC wood carving machine also prioritizes sustainability and environmental responsibility. By optimizing the use of raw materials and minimizing waste, it aligns with the growing movement towards eco-friendly manufacturing practices. This has resonated well with environmentally conscious woodworking businesses, who are increasingly seeking sustainable solutions for their production processes.Furthermore, the company's dedication to customer satisfaction is evident in its comprehensive support and maintenance services for the CNC wood carving machine. Their team of experts provides training, technical assistance, and ongoing maintenance to ensure the smooth operation of the machine, thus maximizing its lifespan and performance.The introduction of the CNC wood carving machine has already made a significant impact on the woodworking industry. It has empowered businesses to take their wood carving capabilities to new heights, unleashing a world of creative possibilities and redefining the standards of craftsmanship. As the demand for precision and efficiency continues to drive the evolution of the woodworking industry, the CNC wood carving machine stands as a testament to the power of innovation and technology in transforming traditional practices.In conclusion, the CNC wood carving machine, developed by a prominent player in the woodworking industry, has revolutionized the way wood products are manufactured. Its advanced technology, versatility, sustainability, and comprehensive support services have positioned it as a game-changer in wood carving. As it continues to gain traction in the market, the CNC wood carving machine is set to redefine the standards of precision and automation in woodworking, setting a new benchmark for the industry.

The Art of Lathe Machine Work: Understanding its Mechanics and Applications in Modern Industries

Title: Innovative Lathe Machine Work: Revolutionizing Precision ManufacturingSubtitle: Cutting-Edge Technology Spearheads Efficiency and Quality in the Manufacturing Industry[City], [Date] - As technology continues to shape the manufacturing landscape, advanced machinery plays a pivotal role in boosting efficiency and precision. One such marvel of engineering is Lathe Machine Work, an innovative solution utilized in various industries to transform raw materials into intricate components. This cutting-edge technology has revolutionized the manufacturing process, ensuring superior quality and increased productivity for numerous businesses worldwide.Lathe Machine Work, developed by the visionary engineers at [Company Name], capitalizes on state-of-the-art technology and unparalleled expertise. Utilizing the power of automation and computerized control systems, it allows for precise cutting, shaping, drilling, and reaming of raw materials such as metals, plastics, and wood. With its ability to produce intricate and complex designs, Lathe Machine Work has become an indispensable tool for industries ranging from automotive to aerospace, maintaining the highest standards in manufacturing excellence.[Company Name], a globally recognized leader in precision engineering, has harnessed the potential of Lathe Machine Work to push the boundaries of manufacturing capabilities. With a rich heritage spanning [number] years, the company has consistently stayed ahead of the curve by investing in groundbreaking technologies. This dedication to innovation has propelled [Company Name] to the forefront of the industry, providing its clients with cutting-edge solutions that meet and exceed their expectations.Combining expertise, creativity, and advanced equipment, [Company Name] has successfully completed a myriad of prestigious projects, solidifying its sterling reputation. From precision components used in renowned space missions to intricate automotive parts in high-performance vehicles, the company has been consistently hailed for its exceptional craftsmanship and attention to detail.Underpinning the success of [Company Name]'s Lathe Machine Work is its team of highly skilled engineers and technicians. The company boasts a multidisciplinary workforce committed to providing tailored solutions to its diverse clientele. Operating with precision and efficiency, these professionals leverage the capabilities of Lathe Machine Work to transform concepts into reality, ensuring the highest level of accuracy, durability, and aesthetics.One of the key advantages of Lathe Machine Work lies in its versatility, accommodating projects of varying scales and complexities. Whether it's producing intricate components for electric vehicles or large-scale fabricated structures for the construction industry, Lathe Machine Work proves to be a versatile tool capable of meeting the demands of virtually any manufacturing process. This flexibility has enabled [Company Name] to expand its reach and offer its services to diverse industries globally.What truly sets [Company Name] apart in the industry is its strong commitment to sustainability and environmental responsibility. The company views its Lathe Machine Work as an instrument for positive change, incorporating eco-friendly practices into every step of the manufacturing process. From utilizing recycled materials to implementing energy-efficient solutions, [Company Name] ensures that its manufacturing practices contribute to a greener and more sustainable future.In conclusion, Lathe Machine Work has emerged as a groundbreaking technology in precision manufacturing, elevating the capabilities of businesses around the world. [Company Name]'s unwavering commitment to innovation and sustainability has placed it at the forefront of the industry, delivering unrivaled precision, quality, and efficiency to its clientele. With the constant advancements in technology, Lathe Machine Work promises to continue pushing the boundaries of manufacturing, revolutionizing industries and shaping a better tomorrow.Contact:[Company Name][Address][Phone Number][Email Address][Website URL]

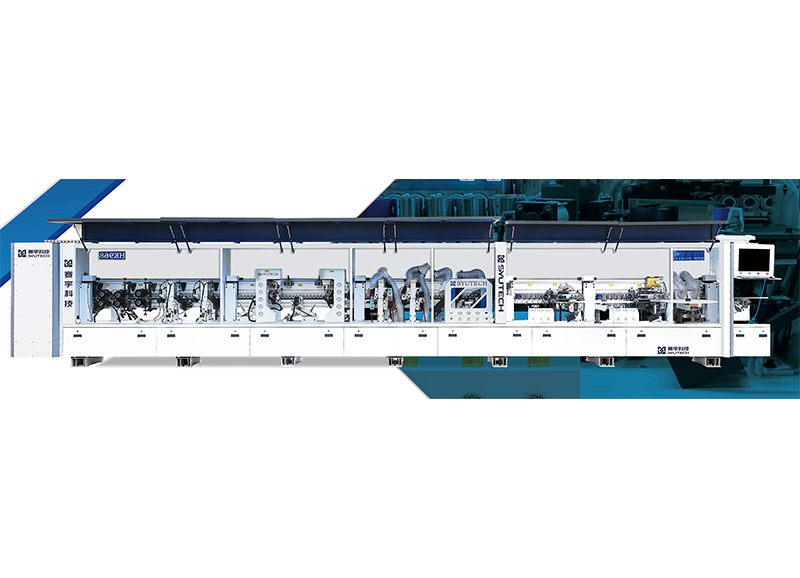

Top Automatic Edge Banding Machine: Everything You Need to Know

News headline: Advanced Automatic Edge Banding Machine Revolutionizes Manufacturing ProcessIn today's fast-paced manufacturing industry, efficiency and precision are key factors in staying competitive. The introduction of advanced machinery has greatly improved the production process, and the recent development of the automatic edge banding machine has further revolutionized the way companies approach edge banding tasks. This state-of-the-art machine is set to transform the manufacturing industry and streamline the production process for companies around the world.The automatic edge banding machine, developed by a leading manufacturing technology solutions company, is equipped with cutting-edge technology and innovative features that are designed to optimize the edge banding process. This machine is capable of handling various types of materials, including wood, plastic, and metal, making it a versatile and essential tool for manufacturers across different industries.The key feature of this automatic edge banding machine is its advanced automation capabilities, which significantly reduce manual labor and increase productivity. The machine is equipped with a high-speed conveyor belt that efficiently moves the materials through the edge banding process, while the automated cutting and trimming mechanisms ensure precise and seamless finishing. This not only improves the overall quality of the end product but also reduces the chances of errors and rework, ultimately saving time and resources for companies.Furthermore, the automatic edge banding machine is designed with user-friendly controls and a simple interface, making it easy for operators to learn and operate the machine with minimal training. This feature is particularly beneficial for companies looking to optimize their production process while minimizing the need for extensive workforce training and supervision.In addition to its advanced automation capabilities, this automatic edge banding machine is also equipped with intelligent sensors and monitoring systems that ensure the safety of the operators and the proper functioning of the machine. This emphasis on safety and reliability is a testament to the company's commitment to providing high-quality and efficient machinery to its customers.With a strong focus on innovation and continuous improvement, the company behind the development of the automatic edge banding machine has established itself as a leader in the manufacturing technology solutions industry. Their dedication to research and development has resulted in the creation of cutting-edge machinery that meets the evolving needs of the manufacturing sector.The automatic edge banding machine is a testament to the company's commitment to providing advanced solutions that enhance the efficiency and productivity of manufacturing operations. By incorporating the latest technology and innovative features into their machinery, the company aims to empower manufacturers with the tools they need to stay ahead in the competitive market.As the manufacturing industry continues to evolve, the introduction of advanced machinery such as the automatic edge banding machine is set to play a pivotal role in shaping the future of manufacturing. With its unparalleled automation capabilities, user-friendly interface, and emphasis on safety and reliability, this machine is poised to become an indispensable asset for companies looking to streamline their production process and stay ahead of the curve.In conclusion, the automatic edge banding machine developed by the company represents a significant advancement in manufacturing technology. Its advanced automation capabilities, user-friendly interface, and emphasis on safety and reliability make it a game-changer for companies looking to improve their edge banding process. As the manufacturing industry continues to embrace innovation, this machine is set to revolutionize the way companies approach edge banding tasks and streamline their production process.

High-Quality Edge Banding for MDF Materials

MDF Edge Banding has long been a leader in the industry, providing high-quality products for the woodworking and furniture manufacturing markets. With a commitment to innovation and customer satisfaction, MDF Edge Banding has established itself as a trusted partner for businesses looking to enhance the appearance and durability of their products.MDF Edge Banding offers a wide range of edge banding solutions, including PVC, ABS, and wood veneer options. Their products are known for their superior quality, precision fit, and variety of color and texture options, making it easy for customers to find the perfect match for their specific needs.MDF Edge Banding is dedicated to providing environmentally friendly solutions, utilizing sustainable materials and manufacturing processes. This commitment to sustainability is reflected in their products, which meet the highest standards for quality and environmental responsibility.In addition to their high-quality products, MDF Edge Banding also offers a range of services to support their customers, including custom color matching, rapid prototyping, and technical support. Their team of experts is available to help customers find the right solution for their specific requirements, ensuring a seamless and satisfying experience from start to finish.With a focus on continuous improvement and innovation, MDF Edge Banding is constantly exploring new technologies and materials to enhance their product offering. Their investment in research and development ensures that they stay ahead of industry trends and deliver cutting-edge solutions to their customers.The company's dedication to excellence has earned them a strong reputation in the market, with a growing customer base that spans the globe. Their products are trusted by leading woodworking and furniture manufacturers, who rely on MDF Edge Banding to deliver reliable, high-quality solutions that meet their exacting standards.MDF Edge Banding's commitment to customer satisfaction is evident in their responsive and flexible approach to business. They pride themselves on their ability to adapt to customer needs, offering personalized solutions that meet the unique requirements of each project.In conclusion, MDF Edge Banding is a leading provider of high-quality edge banding solutions, with a strong track record of delivering exceptional products and services to their customers. With a focus on innovation, sustainability, and customer satisfaction, MDF Edge Banding is well-positioned to continue its success in the market for years to come.

Discover the Latest Updates on Lathe Machines: A Comprehensive Guide

Title: New Mini Lathe Machine Revolutionizes Precision ManufacturingSubtitle: Cutting-Edge Innovation Streamlines Precision Engineering and Boosts Manufacturing EfficiencyIntroduction:In today's fast-paced world, the demand for precision manufacturing has reached unprecedented levels. Timely delivery, superior quality, and cost-effectiveness are key factors that drive success in the manufacturing industry. Recognizing this need, a leading company in the industrial machinery sector has developed an extraordinary new product: the state-of-the-art Mini Lathe Machine.Company Overview:[Company Name], a renowned industry giant with a legacy of unparalleled innovation, has been at the forefront of engineering groundbreaking solutions for over two decades. With a commitment to excellence and a customer-centric approach, [Company Name] has successfully leveraged cutting-edge technology to deliver machinery that revolutionizes manufacturing processes across various industries. The company's unwavering dedication to research and development has earned them a distinguished reputation globally.Product Overview: Mini Lathe MachineThe Mini Lathe Machine, developed by [Company Name], is an exceptional addition to the world of engineering and manufacturing. Combining precision, durability, and ease of use, this innovative machine sets new benchmarks for the industry. From amateur enthusiasts to seasoned professionals, the Mini Lathe Machine caters to a wide range of users.Key Features:1. Unparalleled Precision: The Mini Lathe Machine boasts remarkable precision, ensuring the production of intricate parts with superb accuracy. This cutting-edge technology enables users to meet the most demanding specifications and deliver high-quality products consistently.2. Compact and Portable Design: Unlike its larger counterparts, the Mini Lathe Machine is designed to be compact and highly portable. This feature allows for flexibility in workspace arrangements, making it an ideal solution for small production units or even individual workshops.3. Robust Construction: Engineered with durability in mind, the Mini Lathe Machine is built to withstand heavy usage and provide long-lasting performance. The materials used in its construction are of exceptional quality, guaranteeing longevity and minimal maintenance requirements.4. User-Friendly Interface: [Company Name] has integrated an intuitive interface into the Mini Lathe Machine, making it accessible to users of all skill levels. The user-friendly control panel ensures seamless operation and provides a hassle-free experience.Applications:The Mini Lathe Machine's versatility makes it suitable for a wide range of industries and applications. It finds extensive use in:1. Precision Engineering: From aerospace components to medical devices, the Mini Lathe Machine caters to the intricate demands of precision engineering, enabling the production of high-quality, accurate parts.2. Automotive Industry: The machine's ability to efficiently manufacture small automotive components, such as gears and bearings, contributes to improved production processes within the automotive sector.3. DIY/Enthusiast Projects: The Mini Lathe Machine empowers amateur enthusiasts to explore their creativity and work on thrilling projects, such as woodturning, metalworking, and model making.4. Educational Facilities: With its compact design and ease of use, the Mini Lathe Machine can be an invaluable learning tool in vocational schools and technical training facilities.Conclusion:The Mini Lathe Machine by [Company Name] exemplifies the company's commitment to revolutionizing precision manufacturing. Its exceptional features, coupled with its robust construction, make it a reliable choice for any industry seeking to enhance productivity and maintain stringent quality standards. As [Company Name] continues to innovate and push boundaries, the Mini Lathe Machine stands at the forefront of cutting-edge technology, enabling businesses to streamline their manufacturing processes and remain globally competitive.

Powerful and Safe Table Saw on the Market

Harvey Machinery Group, a leading provider of industrial machinery and equipment, has announced the launch of their latest state-of-the-art table saw. The new table saw, which has been designed and manufactured to the highest standards, promises to revolutionize the woodworking industry with its unparalleled precision, power, and performance.With over 50 years of experience in the industry, Harvey Machinery Group has built a solid reputation for delivering reliable and innovative machinery solutions. The company is known for its commitment to excellence, and their new table saw is no exception. Featuring cutting-edge technology and a durable construction, the table saw is designed to meet the needs of professional woodworkers and hobbyists alike."At Harvey Machinery Group, we are constantly striving to push the boundaries of innovation and quality in our products," said a company spokesperson. "Our new table saw is the result of extensive research and development, and we are confident that it will exceed the expectations of our customers."The table saw boasts a powerful motor that delivers exceptional cutting performance, allowing users to tackle even the toughest woodworking projects with ease. Its precision-machined components ensure smooth and accurate cuts, while the advanced safety features provide peace of mind for users.In addition to its performance capabilities, the table saw is also designed with user convenience in mind. With easy-to-use controls and a robust design, it is a versatile and reliable tool for any woodworking shop. Whether used for ripping, cross-cutting, or bevel cutting, the table saw is capable of handling a wide range of tasks with precision and efficiency.One of the standout features of the table saw is its innovative dust collection system, which helps to maintain a clean and safe working environment. This not only enhances the overall user experience but also contributes to a healthier and more productive workspace.The company has also emphasized the importance of ongoing customer support and service. As part of their commitment to customer satisfaction, Harvey Machinery Group offers comprehensive training and technical assistance to ensure that users can maximize the potential of the table saw."Our goal is not only to provide top-of-the-line machinery, but also to support our customers every step of the way," the spokesperson added. "We want our customers to feel confident in their investment and know that we are here to help them succeed."The launch of the new table saw comes at a time of significant growth for Harvey Machinery Group. With an expanding global presence and a strong focus on innovation, the company is well-positioned to continue leading the way in the woodworking industry."We are excited about the potential of our new table saw and its ability to make a real impact in the industry," said the spokesperson. "We believe that it will set a new standard for performance and reliability, and we look forward to seeing the positive response from our customers."For more information about Harvey Machinery Group and their range of industrial machinery and equipment, visit their website or contact their customer service team.

High-quality Melamine Edge Banding for finishing furniture

Melamine edge banding is a popular material used in the furniture industry for finishing the edges of furniture and cabinetry. It is known for its durability, versatility, and aesthetic appeal. One company that has been making a name in the industry for their high-quality melamine edge banding products is {}. {}{} is a leading manufacturer and supplier of melamine edge banding, with a wide range of colors, sizes, and finishes to meet the diverse needs of their customers. The company takes pride in their state-of-the-art manufacturing facility, which uses advanced technology and processes to ensure the production of top-notch edge banding products.One of the key factors that sets {} apart from other competitors is their commitment to quality. The company uses premium materials and adheres to strict quality control measures to guarantee that their melamine edge banding is of the highest standard. This dedication to quality has earned them a solid reputation in the industry and has made them a preferred choice among furniture manufacturers, interior designers, and contractors.In addition to quality, {} also places a strong emphasis on innovation. They continuously explore new techniques and designs to keep up with the latest trends and demands in the market. This proactive approach has enabled them to offer innovative solutions and customizable options to their customers, making them a reliable partner for all their edge banding needs.Furthermore, {} takes pride in their customer-centric approach. They are committed to providing exceptional customer service, from the initial inquiry to after-sales support. The company’s team of experts is always ready to assist clients in selecting the right edge banding products for their specific requirements and to provide technical advice and guidance as needed.One of the company’s standout products is their extensive range of melamine edge banding options. They offer a wide array of colors and finishes, including solid colors, wood grains, and custom prints, allowing for endless design possibilities. Their edge banding is also available in various widths and thicknesses to accommodate different furniture and cabinetry applications, making it a versatile choice for diverse projects.Another notable feature of {}’s edge banding products is their durability. Their melamine edge banding is designed to withstand daily wear and tear, as well as exposure to moisture and heat, ensuring that the finished furniture or cabinetry maintains its pristine appearance for years to come.With a strong focus on quality, innovation, and customer satisfaction, it is no surprise that {}’s melamine edge banding products have gained widespread acclaim in the industry. Their commitment to excellence has established them as a trusted partner for furniture manufacturers and designers seeking top-notch edge banding solutions.In conclusion, {} is a reputable manufacturer and supplier of melamine edge banding, offering a comprehensive range of high-quality products that cater to the diverse needs of their clients. Their dedication to quality, innovation, and customer satisfaction sets them apart in the industry and makes them a preferred choice for edge banding solutions. As the demand for durable, versatile, and aesthetically pleasing edge banding continues to grow, {} remains at the forefront, providing top-notch products and unparalleled service to their valued customers.

Unlock Your Creativity with an Advanced Router for Wood Carving

Title: Advanced Router Revolutionizes Wood Carving IndustryIntroduction: With the rapid evolution of technology, the art of wood carving has seen a significant shift towards efficiency and precision. One company, at the forefront of this transformation, has introduced an innovative router for wood carving that promises to revolutionize the industry. Combining cutting-edge technology with user-friendly features, this new router is set to redefine the boundaries of wood carving craftsmanship. We take a closer look at this game-changing product and the company's dedication to pushing the limits of creativity.[Company Name], a renowned woodworking equipment manufacturer, has introduced their latest invention marking a significant milestone in the wood carving industry. Focused on combining high-quality design with intricate craftsmanship, the company has aimed to create a router that caters to the needs of both amateur hobbyists and professional woodworkers alike.The new router, which contains an array of advanced features, incorporates computer numerical control (CNC) technology for precise and accurate carving. This ensures that intricate details, complex patterns, and artistic finishes can be achieved with unparalleled precision. With the versatility to engrave even the most intricate designs on a wide range of wood types and sizes, the router has successfully bridged the gap between traditional craft and modern technology.One of the key advantages offered by this router is its user-friendly interface, allowing woodworkers of all skill levels to easily operate the machine. Traditional wood carving methods often require years of training and practice. However, with the introduction of this advanced router, the learning curve has significantly reduced, enabling novices to swiftly create stunning wood carvings. Moreover, the router's intuitive control panel allows users to select patterns, adjust carving depths, and experiment with different techniques effortlessly.Another remarkable feature of this router is its ability to work on large-scale projects easily. The machine's robust frame and cutting-edge spindle motor ensure smooth carving operations, even with substantial and heavy wooden pieces. This capacity makes it an ideal tool for creating breathtaking sculptures, intricate furniture designs, and even detailed architectural elements.The router's compatibility with various software programs further enhances its functionalities and expands its creative possibilities. Woodworkers can import digital designs, edit them as per their requirements, and effortlessly execute them on their chosen wood surfaces. This seamless integration of software and hardware streamlines the creative process and enables woodworkers to actualize their artistic visions with unprecedented ease.In addition to its technical merits, [Company Name] has a strong commitment to sustainability. The new router incorporates eco-friendly features, such as high energy-efficiency and low emission levels. Reducing waste and minimizing environmental impact play a crucial role in the company's ethos.Recognizing the importance of customer support, [Company Name] ensures that purchasers of their routers gain access to comprehensive training resources, including video tutorials, user manuals, and online forums. This robust support network empowers woodworkers to make the most of their router's capabilities and continually sharpen their skills.In conclusion, the introduction of this advanced router for wood carving by [Company Name] signifies a remarkable step forward in the industry. Precision, versatility, ease of use, and environmental considerations all contribute to the router's position as a game-changer in the field of wood carving. Aspiring woodworkers and seasoned professionals alike can now unleash their creativity with unparalleled precision, catering to a growing demand for intricately carved wooden masterpieces. [Company Name]'s dedication to pushing the boundaries of technology and craftsmanship ensures that the art of wood carving continues to flourish in the digital age.

Guide to the Ultimate Woodworking Drill Press: A Comprehensive Review

Woodworking Drill Press Enhances Precision and Efficiency in the Workshop[Company Name], a leading manufacturer and distributor of high-quality woodworking tools and equipment, is pleased to introduce its latest innovation, the Woodworking Drill Press. Designed to meet the demands of professional woodworkers and DIY enthusiasts alike, this state-of-the-art drill press offers precision, power, and versatility for all your drilling needs.With a commitment to excellence and an unwavering focus on providing top-notch tools, [Company Name] continues to establish itself as a trusted brand in the woodworking industry. The Woodworking Drill Press showcases their dedication to engineering innovative solutions that enhance productivity and ensure exceptional results.Built with quality materials and crafted to withstand the rigors of daily use, the Woodworking Drill Press boasts a robust construction. Its durable steel frame provides stability and minimizes vibrations, allowing for accurate drilling in various materials. The carefully machined components, including the drill chuck and table, guarantee smooth operation and precise hole placement.Equipped with a powerful motor, the Woodworking Drill Press delivers ample power to tackle even the toughest drilling tasks. Its variable speed control allows users to adjust the drilling speed to match the material being worked on, ensuring optimal results and preventing any damage. The digital display prominently features the current speed, providing real-time feedback and enabling users to make informed adjustments.One of the standout features of the Woodworking Drill Press is its advanced depth control system. With a simple adjustment mechanism, users can easily set the desired drilling depth, allowing for precise and consistent hole depths throughout the project. This innovative feature eliminates guesswork and ensures uniform results, saving time and effort.Another notable aspect of the Woodworking Drill Press is its versatile table design. The generously sized cast-iron table can be tilted up to 45 degrees in both directions, offering the flexibility needed for angled drilling and beveling tasks. The table also features adjustable clamps and a miter gauge, allowing for secure workholding and accurate angled cuts.In addition to its exceptional drilling capabilities, the Woodworking Drill Press prioritizes user safety. The press is equipped with a transparent and adjustable safety guard that shields the drill bit, preventing any accidental contact with the user's hands during operation. Furthermore, a built-in laser guide system assists in aligning the drilling position, minimizing errors and increasing accuracy.[Company Name] understands the importance of convenience and ease of use. The Woodworking Drill Press is equipped with a quick-release mechanism for efficient and hassle-free tool changes. The smooth and responsive control panel allows users to effortlessly adjust settings and switch between drilling modes, further enhancing productivity and workflow.Furthermore, [Company Name] is known for its comprehensive customer support. With a team of knowledgeable experts, they provide prompt assistance and guidance to ensure that customers have a seamless experience with their products. Additionally, the Woodworking Drill Press comes with a warranty, showcasing the company's commitment to customer satisfaction and product reliability.As the woodworking industry continues to evolve, [Company Name] remains at the forefront, constantly pushing boundaries and introducing groundbreaking tools. The Woodworking Drill Press exemplifies their dedication to excellence, offering woodworkers a reliable and efficient solution that will undoubtedly elevate their craft and transform their workshops.In conclusion, the introduction of the Woodworking Drill Press by [Company Name] marks another significant milestone in their pursuit of delivering top-quality woodworking tools. With its robust construction, powerful motor, advanced features, and focus on user safety, this drill press is poised to revolutionize the way woodworkers approach drilling tasks. Whether you are a professional woodworker or a hobbyist, the Woodworking Drill Press is a must-have addition to your workshop, ensuring precision, efficiency, and superior results.

Efficient Cabinet Hole Drilling Machine for Home Improvement Projects

The industrial sector has always been at the forefront of innovation and development, constantly striving to improve productivity and efficiency. In line with this, a new cabinet hole drilling machine has been introduced by a leading company in the manufacturing industry. With a focus on precision, speed, and reliability, this cutting-edge machine is set to revolutionize the way cabinet holes are drilled in production processes.As a company that has been at the forefront of the manufacturing industry for over two decades, our commitment to delivering high-quality, state-of-the-art machinery has always been unwavering. Our latest offering, the cabinet hole drilling machine, is a testament to our dedication to innovation and excellence. Equipped with advanced technology and robust construction, this machine is designed to meet the needs of modern manufacturing operations.The cabinet hole drilling machine is designed to streamline the process of drilling holes in cabinets, ensuring accuracy and efficiency. With its high-speed drilling capabilities and precise positioning, it is able to deliver consistent and accurate results, significantly reducing production time and minimizing errors. This not only enhances productivity but also ensures the quality of the end product, meeting the high standards of the industry.One of the key features of the cabinet hole drilling machine is its versatility. It is capable of drilling a wide range of hole sizes and patterns, allowing for customization and flexibility in production. This adaptability makes it suitable for various applications within the manufacturing sector, catering to the diverse needs of different industries. Whether it is for kitchen cabinets, office furniture, or storage units, this machine offers the agility to meet the specific requirements of each project.Furthermore, the cabinet hole drilling machine is designed with user convenience in mind. Its intuitive interface and user-friendly controls make it easy to operate, reducing the need for extensive training and minimizing the risk of human errors. Additionally, its durable construction and low maintenance requirements contribute to its cost-effectiveness, ensuring long-term reliability and performance.In line with our commitment to sustainable and environmentally friendly practices, the cabinet hole drilling machine is designed to optimize energy efficiency and minimize waste. By utilizing advanced technologies, it is able to operate with minimal energy consumption while maximizing productivity. This not only reduces the carbon footprint of manufacturing operations but also contributes to cost savings for businesses.The introduction of the cabinet hole drilling machine is a testament to our ongoing dedication to pushing the boundaries of what is possible in the manufacturing industry. We believe that through innovation and technological advancement, we can continue to drive progress and empower businesses to achieve their goals.Looking ahead, we are committed to furthering our research and development efforts to bring even more cutting-edge solutions to the market. We are confident that the cabinet hole drilling machine will set a new standard for precision and efficiency in cabinet production, and we are excited to see the impact it will have on the industry.In conclusion, the cabinet hole drilling machine represents a significant advancement in the manufacturing sector, offering unparalleled precision, speed, and reliability. With its versatility and user-friendly design, it has the potential to transform production processes and drive productivity for businesses across the board. As a company dedicated to innovation and excellence, we are proud to bring this breakthrough technology to the market and look forward to the positive impact it will have on the industry.