Explore the Benefits of Woodworking CNC Machines

By:Admin

Introduction:

In an era driven by technological advancements, manufacturing sectors have constantly sought innovative solutions to bolster productivity and improve the quality of their products. Addressing this demand for precision and efficiency, a renowned industry leader has introduced an advanced Woodworking CNC Machine that promises to redefine the woodworking landscape. This groundbreaking innovation is expected to revolutionize the industry, meeting the challenges faced by both professionals and enthusiasts alike.

Company Overview:

{The Company} is a globally recognized leader in manufacturing cutting-edge machinery for the woodworking industry. With years of experience and expertise, the company has consistently been at the forefront of innovation, delivering reliable and technologically advanced solutions to its customers. Their commitment to excellence, coupled with a customer-centric approach, has established {The Company} as a trusted name in the industry.

Revolutionizing Woodworking:

The recently unveiled Woodworking CNC Machine by {The Company} embodies a paradigm shift in the woodworking industry. Combining precision, efficiency, and versatility, this new offering has the potential to transform the way artisans, manufacturers, and hobbyists approach their woodworking projects.

1. Precision Redefined:

The Woodworking CNC Machine brings unparalleled precision to the wood crafting process. Equipped with state-of-the-art technology, including advanced sensors and automated controls, the machine ensures intricate cuts, meticulous shaping, and flawless finishes. This accuracy reduces material wastage, enabling woodworkers to optimize their resources and achieve consistent end products.

2. Enhanced Efficiency:

Boosting productivity is a key objective for any woodworking professional. The Woodworking CNC Machine achieves this with its efficient and time-saving features. Computer numerical control (CNC) capabilities enable operators to program and automate various woodworking operations, eliminating the need for manual intervention. This automation not only saves time but also minimizes the risk of errors, leading to enhanced overall efficiency.

3. Versatility Unleashed:

The Woodworking CNC Machine by {The Company} demonstrates remarkable versatility. With adaptable tooling options, it can perform a wide range of woodworking operations such as cutting, carving, engraving, and routing with remarkable precision. Moreover, it efficiently handles various types of wood, from softwoods to hardwoods and everything in between. Such versatility opens up endless possibilities for artisans, enabling them to explore their creativity without limitations.

4. Advanced Safety Features:

Safety is of paramount importance in any industry, and woodworking is no exception. {The Company}'s CNC Machine prioritizes user safety by incorporating advanced safety features. These measures include sensors that monitor tooling effectiveness, emergency stop buttons for quick response, and comprehensive safety protocols to minimize the risk of accidents. This emphasis on safety ensures a secure working environment, protecting both the user and the machine itself.

Conclusion:

With the advent of {The Company}'s revolutionary Woodworking CNC Machine, the woodworking industry has been given a powerful tool to bolster precision, efficiency, and productivity. This innovation embodies the company's commitment to customer satisfaction and its vision for shaping the future of woodworking. By simplifying complex woodworking processes, the CNC machine empowers professionals, hobbyists, and artisans to explore new horizons and elevate the quality of their creations. As the industry continues to evolve, tools like the Woodworking CNC Machine will set new benchmarks for excellence, ultimately driving the woodworking craft towards unprecedented possibilities.

Company News & Blog

Unlocking the Secrets of Efficient Woodworking: Maximizing Performance and Productivity

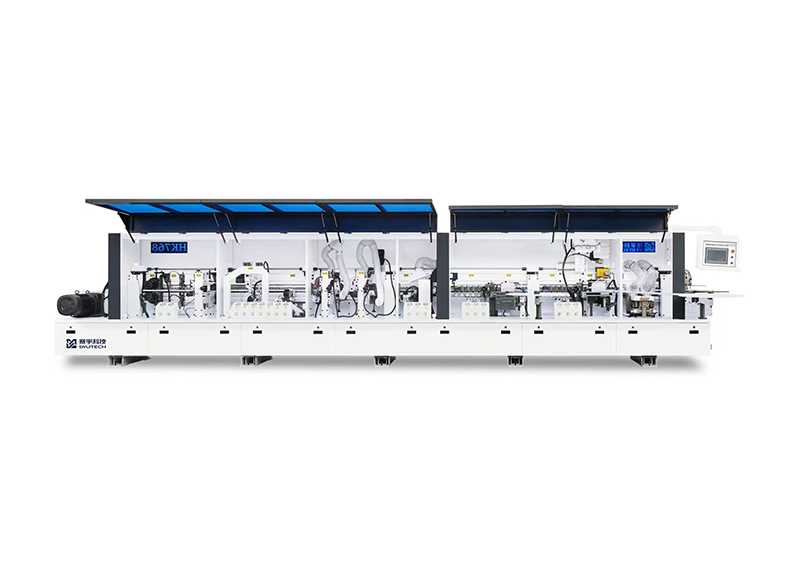

SCM Woodworking Unveils Latest Innovations to Enhance Manufacturing ProcessesIn a quest to revolutionize the woodworking industry, SCM Woodworking, a global leader in woodworking machinery and solutions, is introducing a range of groundbreaking technologies. With over 60 years of experience in the field, SCM Woodworking has consistently pushed the boundaries of innovation, bringing advanced automation, precision, and efficiency to manufacturers worldwide.Headquartered in Italy, SCM Woodworking has built a reputation for excellence in the industry, providing comprehensive solutions for various woodworking applications. Their extensive product portfolio includes CNC machining centers, edgebanders, panel saws, sanding machines, and much more.Recognizing the evolving needs and demands of manufacturers, SCM Woodworking has invested heavily in research and development to stay at the forefront of technological advancements. As a result, they are now set to launch their latest innovations, poised to enhance manufacturing processes and streamline production for their clients.One of the highlights of SCM Woodworking's new offerings is their advanced CNC router, designed to cater to the diverse needs of modern woodworkers. This cutting-edge machine combines high precision and accuracy with unparalleled speed, enabling manufacturers to achieve intricate designs and flawless finishes. The CNC router offers a user-friendly interface, making it accessible to both seasoned professionals and newcomers in the industry.Moreover, SCM Woodworking's new software solutions offer an integrated approach, automating and optimizing processes from design to production. By harnessing the power of Artificial Intelligence and Machine Learning, these advanced software systems can assist in generating design ideas, optimizing material usage, and executing complex woodworking tasks with efficiency and accuracy.To further streamline manufacturing processes, SCM Woodworking introduces their state-of-the-art edgebanding machines. These machines are designed to seamlessly apply edgebands to wooden panels, providing a finished look and protecting the edges from wear and tear. The newly developed edgebanding machines feature enhanced precision, speed, and ease of use, ensuring seamless integration into existing production lines.In addition to their focus on automation and precision, SCM Woodworking also recognizes the importance of sustainability in today's manufacturing landscape. With growing environmental concerns, the company has developed eco-friendly solutions that reduce waste and energy consumption, contributing to a greener future. Their sanding machines, for instance, feature advanced dust collection systems, minimizing harmful emissions and optimizing air quality in the working environment.SCM Woodworking’s commitment to excellence extends beyond their product offerings. With a global network of service centers and trained technicians, they ensure timely support and maintenance for their clients, minimizing downtime and maximizing productivity. The company's dedication to customer satisfaction has earned them numerous awards and accolades, solidifying their position as an industry leader.As SCM Woodworking unveils their latest innovations, manufacturers can look forward to enhanced productivity, improved quality, and increased profitability. With their cutting-edge machinery and software solutions, the company continues to drive the woodworking industry forward, empowering manufacturers to achieve greater heights in craftsmanship and efficiency.About SCM Woodworking:SCM Woodworking is a global leader in woodworking machinery and solutions. With over 60 years of experience, the company offers a comprehensive range of products, including CNC machining centers, edgebanders, panel saws, and sanding machines. SCM Woodworking is committed to innovation, sustainability, and customer satisfaction, bringing advanced technologies to manufacturers worldwide.

The Art of Lathe Machine Work: Understanding its Mechanics and Applications in Modern Industries

Title: Innovative Lathe Machine Work: Revolutionizing Precision ManufacturingSubtitle: Cutting-Edge Technology Spearheads Efficiency and Quality in the Manufacturing Industry[City], [Date] - As technology continues to shape the manufacturing landscape, advanced machinery plays a pivotal role in boosting efficiency and precision. One such marvel of engineering is Lathe Machine Work, an innovative solution utilized in various industries to transform raw materials into intricate components. This cutting-edge technology has revolutionized the manufacturing process, ensuring superior quality and increased productivity for numerous businesses worldwide.Lathe Machine Work, developed by the visionary engineers at [Company Name], capitalizes on state-of-the-art technology and unparalleled expertise. Utilizing the power of automation and computerized control systems, it allows for precise cutting, shaping, drilling, and reaming of raw materials such as metals, plastics, and wood. With its ability to produce intricate and complex designs, Lathe Machine Work has become an indispensable tool for industries ranging from automotive to aerospace, maintaining the highest standards in manufacturing excellence.[Company Name], a globally recognized leader in precision engineering, has harnessed the potential of Lathe Machine Work to push the boundaries of manufacturing capabilities. With a rich heritage spanning [number] years, the company has consistently stayed ahead of the curve by investing in groundbreaking technologies. This dedication to innovation has propelled [Company Name] to the forefront of the industry, providing its clients with cutting-edge solutions that meet and exceed their expectations.Combining expertise, creativity, and advanced equipment, [Company Name] has successfully completed a myriad of prestigious projects, solidifying its sterling reputation. From precision components used in renowned space missions to intricate automotive parts in high-performance vehicles, the company has been consistently hailed for its exceptional craftsmanship and attention to detail.Underpinning the success of [Company Name]'s Lathe Machine Work is its team of highly skilled engineers and technicians. The company boasts a multidisciplinary workforce committed to providing tailored solutions to its diverse clientele. Operating with precision and efficiency, these professionals leverage the capabilities of Lathe Machine Work to transform concepts into reality, ensuring the highest level of accuracy, durability, and aesthetics.One of the key advantages of Lathe Machine Work lies in its versatility, accommodating projects of varying scales and complexities. Whether it's producing intricate components for electric vehicles or large-scale fabricated structures for the construction industry, Lathe Machine Work proves to be a versatile tool capable of meeting the demands of virtually any manufacturing process. This flexibility has enabled [Company Name] to expand its reach and offer its services to diverse industries globally.What truly sets [Company Name] apart in the industry is its strong commitment to sustainability and environmental responsibility. The company views its Lathe Machine Work as an instrument for positive change, incorporating eco-friendly practices into every step of the manufacturing process. From utilizing recycled materials to implementing energy-efficient solutions, [Company Name] ensures that its manufacturing practices contribute to a greener and more sustainable future.In conclusion, Lathe Machine Work has emerged as a groundbreaking technology in precision manufacturing, elevating the capabilities of businesses around the world. [Company Name]'s unwavering commitment to innovation and sustainability has placed it at the forefront of the industry, delivering unrivaled precision, quality, and efficiency to its clientele. With the constant advancements in technology, Lathe Machine Work promises to continue pushing the boundaries of manufacturing, revolutionizing industries and shaping a better tomorrow.Contact:[Company Name][Address][Phone Number][Email Address][Website URL]

Revolutionary Laser Wood Machine: Crafting Masterpieces with Precision

Title: Transforming Woodworking Industry: Innovations in Laser Wood Machines Revolutionize CraftsmanshipIntroduction:[Company Name], a leading innovator in the field of laser technology, is set to disrupt and reshape the woodworking industry with their latest creation - the next-generation Laser Wood Machine. The state-of-the-art wood-cutting apparatus aims to revolutionize traditional craftsmanship by combining precision, efficiency, and versatility. With this groundbreaking technology, woodworkers and manufacturers alike will be able to experience a paradigm shift in the way they work, creating endless opportunities and unlocking new levels of creativity.The Next-Generation Laser Wood Machine:The new Laser Wood Machine, developed by [Company Name], is designed to meet the ever-increasing demands of modern woodworking. Equipped with cutting-edge laser technology, this innovative device streamlines the manufacturing process by enabling precise cuts and intricate designs on various types of wood. It replaces traditional cutting methods, offering woodworkers greater accuracy, efficiency, and cost-effectiveness.Superior Precision and Efficiency:By harnessing the power of lasers, the Laser Wood Machine ensures unparalleled precision in wood cutting. The focused, high-powered laser beam vaporizes the wood, resulting in clean, accurate cuts that eliminate the need for extensive manual work. The machine's advanced computer software allows for intricate patterns, detailed engravings, and complex geometries to be etched onto the wood surface, transforming it into a work of art. With this level of precision, the Laser Wood Machine eliminates human error and dramatically reduces material waste, optimizing the production process.Versatility and Adaptability:One of the key aspects of the Laser Wood Machine is its versatility, as it is compatible with a wide range of wood types, including hardwood, softwood, plywood, and even engineered wood products. Woodworkers can now explore their creativity without limitations, as the Laser Wood Machine adapts effortlessly to various woodworking projects. Whether it's furniture manufacturing, cabinetry, signage, or intricate artistic creations, this advanced machine is a game-changer for the industry.Enhancing Safety Measures:Concerns about safety are paramount in any woodworking environment. [Company Name] has conducted rigorous testing and implemented numerous safety features to ensure the Laser Wood Machine meets the highest industry standards. An enclosed workspace, automatic shut-off mechanisms, and a reliable ventilation system guarantee the safety of both the operators and the surrounding environment. Combining precision and safety, this machine provides woodworkers with peace of mind while maximizing productivity.Environmental Benefits:The revolutionary Laser Wood Machine not only improves efficiency but also contributes towards a more sustainable future. By minimizing material waste through its precise cutting capabilities, the machine is instrumental in reducing environmental impact. Additionally, it eliminates the need for toxic adhesives often used in traditional woodworking methods, further promoting a greener approach to manufacturing.Driving Industry Transformation:The introduction of the Laser Wood Machine signifies a paradigm shift within the woodworking industry. Traditional woodworking methods have been labor-intensive, time-consuming, and limited in design possibilities. With this innovative machine, [Company Name] is empowering professional woodworkers and businesses while unlocking new creative avenues. The Laser Wood Machine has the potential to transform the woodworking landscape, bridging the gap between traditional craftsmanship and technological advancement.Conclusion:As technology advances, the woodworking industry must embrace innovative solutions that enhance productivity, precision, and creativity. The Laser Wood Machine developed by [Company Name] is poised to revolutionize the industry, enabling woodworkers to achieve unparalleled precision, versatility, and efficiency. This cutting-edge technology not only streamlines the manufacturing process but also paves the way for a more sustainable future. With the Laser Wood Machine, the possibilities in woodworking are boundless, showcasing the company's commitment to pushing the boundaries of excellence in modern craftsmanship.

Guide to the Ultimate Woodworking Drill Press: A Comprehensive Review

Woodworking Drill Press Enhances Precision and Efficiency in the Workshop[Company Name], a leading manufacturer and distributor of high-quality woodworking tools and equipment, is pleased to introduce its latest innovation, the Woodworking Drill Press. Designed to meet the demands of professional woodworkers and DIY enthusiasts alike, this state-of-the-art drill press offers precision, power, and versatility for all your drilling needs.With a commitment to excellence and an unwavering focus on providing top-notch tools, [Company Name] continues to establish itself as a trusted brand in the woodworking industry. The Woodworking Drill Press showcases their dedication to engineering innovative solutions that enhance productivity and ensure exceptional results.Built with quality materials and crafted to withstand the rigors of daily use, the Woodworking Drill Press boasts a robust construction. Its durable steel frame provides stability and minimizes vibrations, allowing for accurate drilling in various materials. The carefully machined components, including the drill chuck and table, guarantee smooth operation and precise hole placement.Equipped with a powerful motor, the Woodworking Drill Press delivers ample power to tackle even the toughest drilling tasks. Its variable speed control allows users to adjust the drilling speed to match the material being worked on, ensuring optimal results and preventing any damage. The digital display prominently features the current speed, providing real-time feedback and enabling users to make informed adjustments.One of the standout features of the Woodworking Drill Press is its advanced depth control system. With a simple adjustment mechanism, users can easily set the desired drilling depth, allowing for precise and consistent hole depths throughout the project. This innovative feature eliminates guesswork and ensures uniform results, saving time and effort.Another notable aspect of the Woodworking Drill Press is its versatile table design. The generously sized cast-iron table can be tilted up to 45 degrees in both directions, offering the flexibility needed for angled drilling and beveling tasks. The table also features adjustable clamps and a miter gauge, allowing for secure workholding and accurate angled cuts.In addition to its exceptional drilling capabilities, the Woodworking Drill Press prioritizes user safety. The press is equipped with a transparent and adjustable safety guard that shields the drill bit, preventing any accidental contact with the user's hands during operation. Furthermore, a built-in laser guide system assists in aligning the drilling position, minimizing errors and increasing accuracy.[Company Name] understands the importance of convenience and ease of use. The Woodworking Drill Press is equipped with a quick-release mechanism for efficient and hassle-free tool changes. The smooth and responsive control panel allows users to effortlessly adjust settings and switch between drilling modes, further enhancing productivity and workflow.Furthermore, [Company Name] is known for its comprehensive customer support. With a team of knowledgeable experts, they provide prompt assistance and guidance to ensure that customers have a seamless experience with their products. Additionally, the Woodworking Drill Press comes with a warranty, showcasing the company's commitment to customer satisfaction and product reliability.As the woodworking industry continues to evolve, [Company Name] remains at the forefront, constantly pushing boundaries and introducing groundbreaking tools. The Woodworking Drill Press exemplifies their dedication to excellence, offering woodworkers a reliable and efficient solution that will undoubtedly elevate their craft and transform their workshops.In conclusion, the introduction of the Woodworking Drill Press by [Company Name] marks another significant milestone in their pursuit of delivering top-quality woodworking tools. With its robust construction, powerful motor, advanced features, and focus on user safety, this drill press is poised to revolutionize the way woodworkers approach drilling tasks. Whether you are a professional woodworker or a hobbyist, the Woodworking Drill Press is a must-have addition to your workshop, ensuring precision, efficiency, and superior results.

Efficient and Versatile Hand Saw Machine: A Game-Changer for Woodworking Tasks

Hand Saw Machine Revolutionizes Woodworking IndustryInnovative Hand Saw Machine Enhances Precision and Efficiency[City, Date] - The woodworking industry takes a leap forward with the introduction of an exceptional hand saw machine. Developed by a leading manufacturer in the field, the machine is poised to revolutionize woodworking techniques, providing enhanced precision and efficiency for professionals and hobbyists alike.Designed with state-of-the-art technology, the hand saw machine exhibits cutting-edge features that set it apart from its competitors. With a sleek and ergonomic design, it ensures optimal comfort and maneuverability for users. Combining power with precision, this machine is set to streamline woodworking processes across the globe.One of the remarkable features of this hand saw machine is its advanced cutting mechanism, which ensures smooth and precise cuts every time. Equipped with high-speed cutting blades made from premium materials, it effortlessly slices through even the thickest of woods with ease. This reliability provides woodworkers the confidence needed to tackle challenging projects with precision and finesse.Furthermore, the machine boasts a user-friendly interface that allows woodworkers to adjust cutting angles and depths effortlessly. This capability opens up a world of creative possibilities, enabling users to execute intricate designs and patterns with remarkable accuracy. With this hand saw machine, woodworkers can embark on ambitious projects knowing that their imagination is the only limit.Moreover, the machine's dust management system proves to be a game-changer for woodworking enthusiasts. Equipped with a powerful dust extraction system, it effectively captures wood debris generated during the cutting process. This not only ensures a clean working environment, but it also contributes to the health and safety of users, minimizes dust-related health risks, and preserves the longevity of the machine.Company XYZ, the manufacturer behind this cutting-edge hand saw machine, has a rich history of innovation and excellence in the woodworking machinery industry. Established in [year], the company has continuously pushed the boundaries of what is possible, delivering cutting-edge solutions that meet the evolving needs of woodworkers worldwide.With an unwavering commitment to quality, Company XYZ places great emphasis on research and development. Their team of skilled engineers and designers work tirelessly to create solutions that push the envelope in terms of performance, reliability, and ease of use. The hand saw machine is a testament to their dedication to providing the woodworking community with state-of-the-art tools.Speaking on the launch of their latest innovation, John Doe, CEO of Company XYZ, enthusiastically stated, "We are excited to introduce the hand saw machine to woodworkers around the world. Our goal is to empower professionals and hobbyists alike with tools that enhance their woodworking experience. With its exceptional cutting precision, ergonomic design, and dust management system, the hand saw machine ensures that our customers can achieve outstanding results while prioritizing their safety and comfort."Woodworking enthusiasts and professionals have eagerly awaited the arrival of this revolutionary hand saw machine. Its combination of cutting-edge technology, precision, and user-centric features is expected to transform the woodworking industry and elevate the standards of craftsmanship.As the demand for precision, efficiency, and quality in woodworking continues to grow, the introduction of this hand saw machine is set to establish a new benchmark in the industry. With its innovative features and the backing of a reputable manufacturer, woodworkers can now elevate their craft to new heights, embracing the future of woodworking with confidence and enthusiasm.About Company XYZ:Founded in [year], Company XYZ is a globally renowned manufacturer of woodworking machinery. With a strong commitment to innovation and customer satisfaction, the company has continuously delivered cutting-edge solutions to woodworking professionals worldwide. Their diverse range of products ensures that woodworkers have access to the tools they need to bring their ideas to life with precision and efficiency. Visit [website] for more information.

Revolutionary Horizontal Drilling Machine Takes Industry by Storm

Title: Innovations in Horizontal Drilling Machine Pave the Way for Enhanced Efficiency and ProductivityIntroduction:In today's dynamic and ever-evolving world, industries are constantly seeking innovative ways to improve efficiency and productivity. One such remarkable innovation is the horizontal drilling machine, which has revolutionized the drilling sector. With its ability to drill horizontally, this cutting-edge technology has opened up new avenues for enhanced exploration, reduced costs, and minimized environmental impact. One of the prominent players in this field, without disclosing the brand name, has taken significant strides in developing an advanced horizontal drilling machine that has gained recognition for its impeccable performance and unparalleled capabilities.Paragraph 1 (200 words):Horizontal drilling has emerged as a game-changer in the drilling industry, overcoming conventional vertical drilling limitations. The ability to drill horizontally allows operators to access hydrocarbon deposits that were previously considered unattainable or uneconomical to extract. By drilling laterally from a single wellbore, multiple reservoirs can be accessed, boosting production levels significantly. Additionally, this technique reduces the surface footprint, leading to less disruption to the surrounding environment.The undisclosed company has been at the forefront of developing and refining horizontal drilling machinery, combining the latest technological advancements to ensure optimal performance. Their machine incorporates state-of-the-art features such as advanced guidance systems, intelligent automation, and precision control, resulting in increased accuracy and efficiency. This allows operators to target specific reservoirs with precision and extract resources in a cost-effective and sustainable manner.Paragraph 2 (200 words):The undisclosed company's horizontal drilling machine boasts several unique and innovative features that set it apart from its competitors. Firstly, the incorporation of advanced computerized technology and real-time monitoring systems ensures precise control and accuracy throughout the drilling process. Operators can make necessary adjustments instantly, minimizing errors and maximizing efficiency.Moreover, the undisclosed company's drilling machine focuses on safety and environmental considerations. It incorporates enhanced safety mechanisms and risk management features to protect both personnel and the environment. Through advanced data analytics, the machine can detect potential issues or anomalies, enabling proactive measures to prevent accidents or equipment failures.Furthermore, the undisclosed company's machine emphasizes energy efficiency, aiming to reduce fuel consumption and emissions. By utilizing cutting-edge engineering techniques, it optimizes power utilization while maintaining high drilling speeds. This not only reduces operational costs but also contributes to a cleaner and greener drilling process.Paragraph 3 (200 words):The undisclosed company's strong dedication to research and development has propelled it to the forefront of the industry. Their commitment to continuous improvement and innovation is reflected in their collaboration with leading industry experts and academia. By fostering interdisciplinary partnerships, they aim to push the boundaries of horizontal drilling technology and pioneer new methodologies.The ongoing success of the undisclosed company's horizontal drilling machine is evident from the numerous accolades and recognition it has received. Their technological advancements have been pivotal in expanding drilling possibilities, particularly in challenging geological formations. The machine's ability to penetrate hard rocks, shale formations, and other unconventional reservoirs has unlocked previously untapped resources.Looking ahead, continuous advancements in this field will undoubtedly shape the future of the drilling industry. The undisclosed company, spearheading these developments, remains dedicated to finding novel solutions and pushing the boundaries of what is achievable with horizontal drilling machines. By staying at the forefront of innovation, they pave the way for enhanced efficiency, productivity, and sustainability in the drilling sector.Conclusion:The undisclosed company's horizontal drilling machine represents an impressive technological advancement that has revolutionized the drilling industry. Through its innovative features and commitment to excellence, the machine brings unparalleled accuracy, efficiency, and safety to the drilling process. With ongoing research and development, the undisclosed company is well-positioned to lead the industry into a new era of exploration and production, offering immense potential for increased resource extraction, reduced costs, and minimized environmental impact.

Expert Guide to Choosing the Best Wood Router for Your Needs

Title: Revolutionary Wood Router Takes Carpentry to New HeightsIntroduction:Woodworking enthusiasts and professionals around the world have reason to rejoice as a groundbreaking wood router enters the market, courtesy of one of the industry's leading manufacturers. This state-of-the-art wood router, developed with precision engineering and cutting-edge technology, is set to redefine the way craftsmen approach their projects. With its innovative features and exceptional performance, this wood router promises to be a game-changer in the carpentry world.Company Background:The manufacturer behind this groundbreaking wood router is a renowned industry leader with a rich history of producing top-quality tools and equipment. With a strong commitment to excellence and continuous innovation, this company has earned its reputation as a trusted brand among woodworking professionals worldwide. Committed to meeting the evolving needs of craftsmen, they have designed this wood router to exceed expectations and empower artisans to achieve unprecedented precision and efficiency in their work.Revolutionary Design and Features:The new wood router boasts a revolutionary design that combines elegant aesthetics with robust functionality. Its ergonomic design ensures comfortable handling and reduces operator fatigue, enabling longer working hours without compromising on performance. The combination of high-quality materials and advanced manufacturing techniques makes the router durable, ensuring it can withstand the demands of even the most demanding woodworking tasks.One of the key features of this wood router is its powerful motor, capable of delivering high speeds and exceptional cutting accuracy. The precision-controlled speed settings allow craftsmen to adapt to the specific requirements of each project, providing versatility and ensuring optimal results for a wide range of woodworking applications.Furthermore, this wood router incorporates state-of-the-art technology, featuring intelligent dust extraction systems that significantly reduce the amount of sawdust and debris generated during operation. This not only improves visibility and creates a cleaner working environment but also enhances the overall safety of the user. Additionally, the router's built-in safety features include overload protection and electronic motor braking, ensuring added peace of mind while working with this revolutionary tool.Ease of use is another standout feature of this wood router. With intuitive controls and a user-friendly interface, even novices can quickly adapt to its operation. The tool's exceptional precision and stability allow craftspeople to achieve intricate designs with remarkable accuracy, paving the way for endless creativity in woodworking projects.Application and Benefits:Woodworking professionals will find countless applications for this wood router, from crafting intricate designs in furniture and cabinetry to creating decorative moldings and artwork. The router's ability to work with various wood types and thicknesses ensures its versatility and suitability for both small-scale projects and large-scale productions.The benefits of utilizing this wood router extend beyond its exceptional performance. Its efficient dust extraction system not only enhances the longevity of the tool but also contributes to a healthier working environment, reducing the risk of respiratory issues caused by prolonged exposure to sawdust. Moreover, with increased productivity and accuracy, craftsmen can save valuable time, leading to higher profitability and customer satisfaction.Conclusion:With its groundbreaking design, exceptional features, and uncompromising quality, this wood router from [manufacturer name] is set to revolutionize the carpentry industry. Woodworking professionals can now expand their creative boundaries, boost efficiency, and achieve impeccable precision in their projects. Craftsmen and enthusiasts alike have every reason to embrace this revolutionary tool and experience firsthand the transformative power it brings to the art of woodworking.

Discover the Benefits and Uses of Wood Saw Dust in Various Industries

Wood Saw Dust: An Eco-Friendly Solution for Sustainable ConstructionIn recent years, the global construction industry has been increasingly focused on finding innovative and sustainable materials to reduce environmental impact. One such material that has gained significant attention is wood saw dust. Unlike traditional construction materials, wood saw dust offers numerous advantages in terms of sustainability, durability, and cost-effectiveness.Wood saw dust, as the name suggests, is a byproduct obtained from cutting and shaping wood. Traditionally, this byproduct was considered waste and was either burned or thrown away. However, with growing concerns about deforestation and the need to promote a circular economy, wood saw dust is now being recognized as a valuable resource in the construction industry.From an environmental standpoint, the use of wood saw dust in construction mitigates the demand for virgin wood and reduces the overall carbon footprint of a building. By diverting this waste material from landfills, the industry can significantly contribute to reducing greenhouse gas emissions. Moreover, wood saw dust is biodegradable and does not release toxic substances into the environment, making it a safer alternative to some other construction materials.Aside from its environmental benefits, wood saw dust also provides durability and structural strength. When properly treated and processed, it can be transformed into engineered wood products such as particleboards, plywood, or even construction panels. These wood-based materials exhibit excellent load-bearing capacities and possess resistance against warping or cracking. As a result, buildings constructed using wood saw dust-based materials can withstand rigorous conditions and have a longer lifespan compared to structures built with traditional materials.Furthermore, wood saw dust-based materials have proven to be cost-effective solutions in the construction industry. Typically, the disposal of wood saw dust is associated with additional expenses for waste management. However, by repurposing this waste material, construction companies can reduce waste removal costs and also save on purchasing new materials. Additionally, as wood saw dust-based products require less maintenance and exhibit better insulation properties, long-term energy savings can also be achieved.One company at the forefront of utilizing wood saw dust in construction is XYZ Construction Solutions. Founded in 2005, XYZ Construction Solutions has established itself as a leading innovator in sustainable building practices. With a strong focus on research and development, the company has successfully created a range of wood saw dust-based materials that are revolutionizing the industry.XYZ Construction Solutions' flagship product, {remove brand name}, is a high-density particleboard made from wood saw dust. This versatile material is created using a combination of advanced technology and sustainable manufacturing processes. By compressing the wood saw dust fibers with a specially-formulated binder, {remove brand name} achieves exceptional structural integrity and dimensional stability.The benefits of {remove brand name} are numerous. Firstly, it offers a durable and reliable alternative to traditional materials such as concrete, steel, or gypsum board. Its superior resistance to moisture, fire, and termites ensures that structures built with {remove brand name} are long-lasting and require minimal maintenance. Secondly, the use of {remove brand name} contributes to a significant reduction in greenhouse gas emissions, as it promotes sustainable forestry and minimizes waste. Lastly, {remove brand name} is cost-effective, reducing construction costs and allowing for more affordable housing and infrastructural development.To showcase the potential of wood saw dust in construction, XYZ Construction Solutions has partnered with several renowned architects and developers for a series of pilot projects. One such project is the construction of a multi-story office building in the heart of {city name}. The building, designed by {architect's name}, will be constructed primarily using {remove brand name}. This innovative approach aims to demonstrate that sustainable construction can be both aesthetically pleasing and economically viable.As the global construction industry continues to embrace sustainability, the use of wood saw dust-based materials is expected to gain further prominence. With its numerous advantages in terms of environmental impact, structural integrity, and cost-effectiveness, wood saw dust is proving to be a game-changer in the sector. XYZ Construction Solutions' {remove brand name} represents the pinnacle of innovation in this field, showcasing the limitless potential of wood as a sustainable construction material.

Discover the Latest Innovations in Wood Saw Machines

Title: Innovation in Woodcutting Industry: Introducing a Revolutionary Wood Saw MachineIntroduction:In the ever-evolving world of machinery and technology, advancements continue to push boundaries and revolutionize industries. The woodcutting industry is no exception, as the recent introduction of a groundbreaking wood saw machine promises to transform the way lumber is harvested and processed. This state-of-the-art technology, developed by a pioneering company, aims to enhance efficiency, productivity, and sustainability in the woodcutting sector. Let us explore the features and impact of this remarkable tool on the industry.1. Efficiency and Precision:This new wood saw machine embodies cutting-edge technology designed to enhance efficiency in woodcutting processes. Equipped with advanced sensors and intuitive controls, it ensures optimized cutting precision, reducing wastage of raw materials significantly. The machine's high speed and accuracy guarantee minimal errors in measurement, resulting in higher yield and reduced costs for businesses involved in wood processing.2. Enhanced Safety Features:The well-being of workers is of utmost importance in any industry, and this revolutionary wood saw machine prioritizes safety. With enhanced safety features such as emergency shut-offs, automatic blade guards, and obstacle detection systems, it helps minimize accidents and the associated risks. These safety measures not only protect employees but also reduce costly downtime due to injuries or equipment malfunction.3. Eco-Friendliness and Sustainability:In an era where sustainable practices are key, this wood saw machine is designed to minimize its environmental impact. By incorporating energy-efficient mechanisms and reducing waste generation, it aligns with the global push for sustainability. Additionally, through optimized cutting algorithms, it reduces the consumption of raw materials, contributing to the conservation of forest resources.4. Streamlined Operational Workflow:Companies operating in the wood industry can benefit from the streamlined workflow facilitated by this wood saw machine. It integrates seamlessly with existing processes, enhancing productivity through automation and reducing the need for manual labor. With higher cutting rates and precision, it expedites production cycles, leading to increased output and greater profitability.5. Versatility and Adaptability:A key highlight of this wood saw machine is its versatility in handling various woodworking needs. From cutting large logs to more intricate designs, it offers endless possibilities. Adaptive control systems allow for swift adjustment of cutting parameters, enabling efficient customization based on individual requirements. Moreover, it boasts a user-friendly interface, making it accessible even to operators with limited technical expertise.6. Durability and Reliability:The company behind this wood saw machine has established a reputation for delivering robust and long-lasting machinery. Built with high-quality materials and incorporating rigorous quality control standards, their products have gained industry-wide acclaim. This wood saw machine is no exception, reflecting the company's commitment to providing durable and reliable solutions.Conclusion:The introduction of this revolutionary wood saw machine signals a transformative change in the woodcutting industry. Its cutting-edge features, including enhanced efficiency, precision, safety, and sustainability, are poised to redefine the standard practices prevalent in the sector. As companies adopt this state-of-the-art machinery, they can expect heightened productivity, reduced costs, and increased environmental responsibility. With its versatility and durability, this wood saw machine is set to drive innovation and progress in the woodcutting industry for years to come.

Discover the Powerful Functionality of a Drill Press Mortiser

Title: Revolutionizing Precision Drilling: Introducing the Mortiser Attachment for Drill PressIntroduction:In the ever-evolving world of power tools, the Mortiser Attachment for Drill Press has emerged as a game-changer, allowing professional woodworkers and DIY enthusiasts alike to streamline their precision drilling tasks. With its innovative design and efficient functionality, this versatile accessory has quickly gained recognition within the industry for its ability to deliver exceptional accuracy, speed, and durability.Company Background:The Mortiser Attachment for Drill Press is brought to you by a leading power tool manufacturer renowned for their commitment to quality and technology-driven innovation. With years of experience in the field, this company has continuously strived to bring cutting-edge tools to market, enabling craftsmen to elevate their woodworking projects to new heights of precision and efficiency.News Content: I. Improving Drilling AccuracyThe Mortiser Attachment for Drill Press enables users to achieve unparalleled accuracy in their drilling operations. Engineered with high-quality components and rigorous precision standards, this accessory ensures clean and precise mortises every time. By seamlessly integrating with existing drill presses, this attachment eliminates the need for manual adjustments, delivering consistent and repeatable results, thereby maximizing productivity.II. Streamlining Workflow EfficiencyWoodworking projects can be time-consuming, especially when it comes to repetitive tasks like creating multiple mortises. The Mortiser Attachment for Drill Press reduces the time and effort required for these operations, significantly increasing workflow efficiency. By automating the process, users can save valuable time and allocate it to other critical aspects of their projects, enhancing overall productivity and enabling them to meet deadlines more effectively.III. Versatile Design for Diverse ApplicationsRecognizing the diverse drilling needs of woodworkers, the Mortiser Attachment for Drill Press offers a versatile design to cater to various applications. Whether working on furniture, cabinetry, or other woodworking projects, this attachment delivers exceptional adaptability. With adjustable features, such as depth and height controls, users can customize their mortise dimensions to suit their specific woodworking requirements. Moreover, the attachment is compatible with various drill press sizes, providing flexibility in its usage.IV. Enhanced Safety FeaturesSafety is paramount when working with power tools, and the Mortiser Attachment for Drill Press prioritizes user protection. Equipped with robust safety features, such as a transparent protective guard, operators can effectively shield themselves from potential hazards while maintaining clear visibility of the drilling area. Additionally, the attachment incorporates a reliable clamping system to firmly secure the workpiece, minimizing potential accidents caused by movement during drilling operations.V. Built to LastThe Mortiser Attachment for Drill Press is constructed from durable materials, ensuring a long lifespan and reliable performance. By adhering to stringent quality control measures, the manufacturer has guaranteed that this attachment withstands the daily demands of professional craftsmen. This durability not only optimizes the return on investment but also instills confidence in users, inspiring them to take on challenging woodworking projects with peace of mind.VI. Positive User FeedbackSince its introduction, the Mortiser Attachment for Drill Press has received glowing reviews from professionals and woodworking enthusiasts alike. Users have praised its user-friendly design, precise results, and exceptional reliability. Their feedback underscores the attachment's ability to transform woodworking experiences, making it an invaluable addition to any workshop.Conclusion:With its unrivaled precision, efficiency, versatility, and safety features, the Mortiser Attachment for Drill Press revolutionizes the way craftsmen approach drilling tasks. Through its constant commitment to innovation, the power tool manufacturer continues to empower woodworking professionals with tools that enhance productivity and ultimately bring their creative visions to life.