High-Quality Edgebander Tape for All Your Woodworking Needs

By:Admin

The cabinet making industry has seen a revolution with the introduction of [Company Name]'s innovative Edgebander Tape. The company has been a leader in providing high-quality solutions for the woodworking and furniture industries, and their latest product has taken the industry by storm.

[Company Name] has been a trusted name in the woodworking industry for over 20 years. With its commitment to innovation and quality, the company has remained at the forefront of providing cutting-edge solutions for cabinet makers and furniture manufacturers. The launch of their Edgebander Tape is a testament to their dedication to meeting the evolving needs of their customers.

The Edgebander Tape is a game-changer for cabinet makers as it offers a cost-effective and efficient solution for edgebanding. Traditional edgebanding methods often require the use of adhesives and specialized equipment, which can be time-consuming and labor-intensive. However, [Company Name]'s Edgebander Tape simplifies the process by providing a convenient and reliable alternative.

One of the key features of the Edgebander Tape is its ease of use. Cabinet makers can simply apply the tape to the edges of their furniture or cabinet pieces and use a standard edgebander machine to achieve a seamless and durable finish. This not only saves time but also reduces the need for specialized skills, making it an ideal solution for both small-scale workshops and large manufacturing facilities.

In addition to its ease of use, the Edgebander Tape also offers superior performance and durability. The tape is made from high-quality materials that are designed to withstand the rigors of everyday use. This ensures that the edges of the furniture or cabinets remain protected and secure, providing a long-lasting finish that meets the highest standards of quality.

Furthermore, the Edgebander Tape is available in a wide range of colors and finishes, allowing cabinet makers to achieve a customized look for their products. This level of versatility is a significant advantage for manufacturers who cater to diverse customer preferences and design aesthetics. Whether it's a sleek and modern finish or a classic and traditional look, the Edgebander Tape delivers exceptional results every time.

The introduction of [Company Name]'s Edgebander Tape has garnered high praise from cabinet makers and furniture manufacturers alike. Many have lauded the product for its ability to streamline production processes and improve the overall quality of their products. This has ultimately translated to higher customer satisfaction and increased profitability for businesses that have integrated the tape into their operations.

Moreover, the Edgebander Tape has also been recognized for its environmental benefits. By eliminating the need for solvent-based adhesives, the tape reduces harmful emissions and promotes a greener approach to woodworking. This aligns with [Company Name]'s commitment to sustainability and responsible manufacturing practices, further cementing their reputation as an industry leader.

Looking ahead, [Company Name] continues to innovate and expand its product offerings to meet the evolving needs of the woodworking and furniture industries. With the successful launch of the Edgebander Tape, the company has set a new standard for edgebanding solutions and has demonstrated its unwavering dedication to providing practical and high-quality products for its customers.

In conclusion, [Company Name]'s Edgebander Tape has had a significant impact on the cabinet making industry, offering a cost-effective, efficient, and versatile solution for edgebanding. With its ease of use, superior performance, and environmental benefits, the tape has garnered widespread acclaim and has solidified [Company Name]'s position as a leader in providing innovative solutions for the woodworking and furniture industries.

Company News & Blog

Latest Developments in Machinery and Equipment

[Company Name] Expands Machinery and Equipment Offering to Meet Growing Demand[City], [Date] - [Company Name], a leading provider of industrial solutions, has recently expanded its range of machinery and equipment to cater to the ever-increasing demand in various industries. With a strong focus on innovation and customer satisfaction, the company is set to redefine the standards of efficiency and productivity.As industries worldwide continue to evolve, the need for cutting-edge machinery and equipment has become paramount. Recognizing this demand, [Company Name] has invested heavily in research and development to bring forth a comprehensive range of solutions that cater to diverse industrial needs. By leveraging the latest technologies and materials, the company is committed to delivering top-notch performance and reliability.One of the company's groundbreaking offerings is the innovative [Product Category]. This state-of-the-art machinery has been developed in collaboration with industry experts to address the specific challenges faced by businesses in sectors such as manufacturing, construction, and logistics. With its advanced features, such as [mention unique features], the [Product Category] promises to revolutionize operations and enhance overall productivity.In addition to [Product Category], [Company Name] has also introduced several other cutting-edge equipment designed to optimize efficiency and workflow. For instance, the [Product Category] offers unrivaled precision and accuracy, ensuring that businesses can streamline their processes and minimize downtime. Moreover, the newly launched [Product Category] is equipped with advanced safety features, prioritizing the well-being of workers and compliance with industry regulations.To ensure seamless integration of these advanced machinery and equipment solutions, [Company Name] also provides comprehensive after-sales support and maintenance services. By offering regular inspections, timely repairs, and prompt spare parts replacement, the company strives to minimize any potential disruptions and maximize its customers' return on investment.Aside from its commitment to innovation, [Company Name] is also dedicated to sustainability and environmental responsibility. The new machinery line has been designed with energy efficiency in mind, reducing both operational costs and carbon emissions. By embracing sustainable manufacturing practices and encouraging responsible usage, the company aims to contribute to a greener future.With its expanded range, [Company Name] is poised to meet the growing demands of its customers across various industries. The company's continuous efforts to enhance product quality, incorporate customer feedback, and adapt to market trends have established it as a trusted partner for businesses seeking reliable industrial solutions.The success of [Company Name] can be attributed not only to its cutting-edge products but also its unwavering commitment to customer satisfaction. Deeply invested in fostering long-lasting relationships, the company ensures that every client receives personalized attention and tailored solutions to meet their unique requirements. By collaborating closely with customers, [Company Name] aims to drive their success and position itself as the partner of choice.Looking ahead, [Company Name] envisions further expansion and innovation. The company remains dedicated to providing groundbreaking machinery and equipment solutions that enable businesses to thrive in an ever-changing industrial landscape. By embracing emerging technologies and anticipating market trends, [Company Name] aims to set new benchmarks for excellence and cement its position as an industry leader.About [Company Name]:[Company Name] is a renowned provider of industrial solutions, specializing in the design, production, and distribution of high-quality machinery and equipment. With a global presence and extensive industry experience, [Company Name] aims to empower businesses with innovative and sustainable solutions that drive productivity and growth. With a focus on customer satisfaction, the company is committed to delivering superior performance and ensuring the success of its clients.For media inquiries, please contact:[Company Name][Contact Person][Address][Phone][Email]

Top Woodworking CNC Machines for Precision Woodwork

Woodworking CNC Machine Revolutionizes Company's Production Process {Company Name} is a leading manufacturer of high-quality wooden furniture and home decor. With a commitment to using the latest technology to enhance their production process, the company recently invested in a state-of-the-art woodworking CNC machine to take their operations to the next level.The woodworking CNC machine, known for its precision and efficiency, has completely revolutionized the way {Company Name} produces its products. The fully automated machine is capable of carrying out complex woodworking tasks with unparalleled accuracy and speed, allowing the company to significantly increase its production capacity while maintaining the highest standard of quality.{Company Name} has always been dedicated to staying at the forefront of innovation in the woodworking industry, and the addition of the CNC machine is a clear reflection of this commitment. By integrating cutting-edge technology into their production process, the company is able to stay ahead of the competition and meet the growing demands of their customers.The woodworking CNC machine is equipped with advanced features that enable it to perform a wide range of woodworking tasks with maximum precision. The machine's ability to carve intricate designs, drill holes, and cut wood with unmatched accuracy has greatly expanded the possibilities for {Company Name} in terms of product design and customization.Furthermore, the CNC machine has significantly reduced the margin of error in the production process, resulting in a higher level of consistency and quality in the finished products. This has not only improved customer satisfaction but has also minimized waste and rework, ultimately leading to cost savings for the company.In addition to its impressive performance, the woodworking CNC machine has also had a positive impact on the company's workforce. By automating many of the repetitive and physically demanding tasks, the machine has allowed employees to focus on more value-added activities such as product design, quality control, and customer service.{Company Name}'s investment in the woodworking CNC machine is a testament to their dedication to remaining at the forefront of the woodworking industry. By leveraging the power of advanced technology, the company is able to enhance its production capabilities, improve product quality, and streamline its operations to meet the needs of a rapidly evolving market.The implementation of the CNC machine has not only increased the company's production capacity but has also opened up new opportunities for growth and expansion. With the ability to create more intricate and customized products, {Company Name} is well-positioned to attract a broader customer base and establish itself as a leader in the woodworking industry.Looking ahead, {Company Name} is committed to exploring further opportunities to leverage technology to drive innovation and enhance its competitive edge. The company remains dedicated to staying ahead of the curve and delivering high-quality products that exceed customer expectations.In conclusion, the woodworking CNC machine has been a game-changer for {Company Name}, allowing the company to elevate its production process to new heights. By embracing the latest technology and incorporating it into their operations, {Company Name} has set a new standard for excellence in the woodworking industry. As the company continues to grow and evolve, it is poised to achieve even greater success with the support of its cutting-edge CNC machine.

Explore the Benefits of Woodworking CNC Machines

Title: Revolutionary Woodworking CNC Machine Unveiled, Paving the Way for Precision and EfficiencyIntroduction:In an era driven by technological advancements, manufacturing sectors have constantly sought innovative solutions to bolster productivity and improve the quality of their products. Addressing this demand for precision and efficiency, a renowned industry leader has introduced an advanced Woodworking CNC Machine that promises to redefine the woodworking landscape. This groundbreaking innovation is expected to revolutionize the industry, meeting the challenges faced by both professionals and enthusiasts alike.Company Overview:{The Company} is a globally recognized leader in manufacturing cutting-edge machinery for the woodworking industry. With years of experience and expertise, the company has consistently been at the forefront of innovation, delivering reliable and technologically advanced solutions to its customers. Their commitment to excellence, coupled with a customer-centric approach, has established {The Company} as a trusted name in the industry.Revolutionizing Woodworking:The recently unveiled Woodworking CNC Machine by {The Company} embodies a paradigm shift in the woodworking industry. Combining precision, efficiency, and versatility, this new offering has the potential to transform the way artisans, manufacturers, and hobbyists approach their woodworking projects.1. Precision Redefined:The Woodworking CNC Machine brings unparalleled precision to the wood crafting process. Equipped with state-of-the-art technology, including advanced sensors and automated controls, the machine ensures intricate cuts, meticulous shaping, and flawless finishes. This accuracy reduces material wastage, enabling woodworkers to optimize their resources and achieve consistent end products.2. Enhanced Efficiency:Boosting productivity is a key objective for any woodworking professional. The Woodworking CNC Machine achieves this with its efficient and time-saving features. Computer numerical control (CNC) capabilities enable operators to program and automate various woodworking operations, eliminating the need for manual intervention. This automation not only saves time but also minimizes the risk of errors, leading to enhanced overall efficiency.3. Versatility Unleashed:The Woodworking CNC Machine by {The Company} demonstrates remarkable versatility. With adaptable tooling options, it can perform a wide range of woodworking operations such as cutting, carving, engraving, and routing with remarkable precision. Moreover, it efficiently handles various types of wood, from softwoods to hardwoods and everything in between. Such versatility opens up endless possibilities for artisans, enabling them to explore their creativity without limitations.4. Advanced Safety Features:Safety is of paramount importance in any industry, and woodworking is no exception. {The Company}'s CNC Machine prioritizes user safety by incorporating advanced safety features. These measures include sensors that monitor tooling effectiveness, emergency stop buttons for quick response, and comprehensive safety protocols to minimize the risk of accidents. This emphasis on safety ensures a secure working environment, protecting both the user and the machine itself.Conclusion:With the advent of {The Company}'s revolutionary Woodworking CNC Machine, the woodworking industry has been given a powerful tool to bolster precision, efficiency, and productivity. This innovation embodies the company's commitment to customer satisfaction and its vision for shaping the future of woodworking. By simplifying complex woodworking processes, the CNC machine empowers professionals, hobbyists, and artisans to explore new horizons and elevate the quality of their creations. As the industry continues to evolve, tools like the Woodworking CNC Machine will set new benchmarks for excellence, ultimately driving the woodworking craft towards unprecedented possibilities.

Powerful Circular Saw Machine for Efficient Cutting

Circular Saw Machine: The Next Breakthrough in Industrial Cutting TechnologyIn the ever-evolving world of industrial machinery, innovation is the key to staying ahead of the competition. A breakthrough in cutting technology has arrived with the introduction of the circular saw machine by a leading manufacturer in the industry. This state-of-the-art equipment is set to revolutionize the way materials are cut, providing unparalleled precision, efficiency, and reliability.The circular saw machine, developed by a team of experienced engineers and designers, is designed to meet the high demands of modern industrial applications. With its advanced features and cutting-edge technology, this machine is capable of handling a wide range of materials, including wood, metal, plastic, and more.One of the key highlights of the circular saw machine is its precision cutting capabilities. Equipped with high-quality blades and a powerful motor, this machine ensures clean and accurate cuts, minimizing material wastage and enhancing productivity. Whether it's straight cuts, bevel cuts, or cross cuts, the circular saw machine delivers exceptional results every time.Furthermore, the machine is designed with user convenience in mind. Its intuitive control panel and ergonomic design make it easy to operate, significantly reducing the learning curve for operators. Additionally, safety features such as blade guards and emergency stop mechanisms ensure a secure working environment for the operators.The company behind this groundbreaking innovation is a renowned name in the industrial machinery sector. With a legacy of delivering top-quality equipment and a commitment to ongoing research and development, the company has earned a reputation for excellence and reliability. Their dedication to providing cutting-edge solutions to meet the evolving needs of the industry is evident in the design and performance of the circular saw machine.In addition to its innovative products, the company also takes pride in its customer service and support. With a global network of service centers and a team of knowledgeable professionals, they are committed to ensuring that their customers receive prompt assistance and expert guidance whenever needed. This dedication to customer satisfaction sets them apart as a trusted partner for businesses across various industries.The introduction of the circular saw machine marks a significant milestone for the company and the industry as a whole. As businesses continue to seek ways to improve efficiency and accuracy in their operations, this advanced cutting technology offers a compelling solution. Whether it's for woodworking, metal fabrication, or other industrial applications, the circular saw machine is poised to set new standards in precision cutting and productivity.Industry experts and business owners alike are taking notice of this exciting development. The potential impact of the circular saw machine on streamlining production processes and enhancing the quality of finished products is generating significant interest and anticipation.With its combination of cutting-edge technology, precision performance, and user-friendly design, the circular saw machine is set to become a game-changer for the industrial cutting sector. As businesses look towards the future of manufacturing and production, this innovative equipment offers a glimpse of the possibilities that lie ahead.In conclusion, the introduction of the circular saw machine represents a significant advancement in industrial cutting technology. With its precision cutting capabilities, user-friendly design, and the backing of a reputable manufacturer, this equipment is poised to make a lasting impact on the industry. As businesses embrace this cutting-edge solution, they stand to gain a competitive edge in their operations while setting new standards for efficiency and quality. The future of industrial cutting has arrived, and it comes in the form of the revolutionary circular saw machine.

High-Quality Edge Banding Machines from Russia: A comprehensive guide

Russia has recently developed a new edge banding machine that is set to revolutionize the woodworking industry. This cutting-edge technology is expected to increase efficiency and productivity in the manufacturing process, making it a game-changer for woodworking companies around the world.The edge banding machine, developed by a leading Russian manufacturing company, is designed to apply edge banding to wood panels with precision and speed. This new technology boasts advanced features that set it apart from traditional edge banding machines, making it an attractive option for woodworking companies looking to streamline their production process.One of the key features of the new edge banding machine is its ability to handle a wide range of edge banding materials, including PVC, ABS, and wood veneer. This versatile capability allows woodworking companies to work with different types of materials, offering them greater flexibility in their production processes.In addition, the edge banding machine is equipped with advanced automation technology, allowing for smooth and efficient operation. This automation not only increases the speed of production but also ensures consistent and high-quality results, meeting the demands of modern manufacturing standards.Furthermore, the edge banding machine is designed with user-friendly controls, making it easy for operators to set up and operate the machine. This intuitive interface reduces the learning curve for new users, allowing woodworking companies to maximize the machine's potential from the get-go.Another standout feature of the new edge banding machine is its durability and reliability. Built with high-quality materials and precision engineering, this machine is designed to withstand the rigors of heavy-duty production in woodworking facilities. This means that companies can rely on the machine to perform consistently and deliver results over the long term.The Russian manufacturing company behind this innovative edge banding machine has a strong track record in producing high-quality woodworking machinery. With a focus on innovation and customer satisfaction, the company has established itself as a leader in the industry, continually pushing the boundaries of what is possible in woodworking technology.The company's commitment to research and development has led to the creation of this groundbreaking edge banding machine, which is poised to make a significant impact on the global woodworking market. By leveraging its expertise and experience, the company has succeeded in developing a product that addresses the needs of modern woodworking companies, offering a solution that combines efficiency, versatility, and reliability in one powerful package.As woodworking companies strive to keep up with growing demand and evolving industry standards, the new edge banding machine from Russia presents an opportunity to enhance their production capabilities and stay ahead of the competition. With its advanced features, user-friendly design, and reputation for quality, this machine is set to become a valuable asset for woodworking companies looking to elevate their manufacturing processes.In conclusion, the new edge banding machine from Russia represents a significant advancement in woodworking technology, offering a range of features and capabilities that promise to transform the way wood panels are finished. With its versatility, automation, durability, and user-friendly design, this machine is well-positioned to make a lasting impact on the woodworking industry, providing companies with the tools they need to thrive in today's competitive market.

Efficient and Precision CNC Side Grooving Machines: Boost Your Productivity

[Company Name] Introduces Innovative CNC Side Grooving Machine for Enhanced Precision and Efficiency[CITY, DATE] - [Company Name], a leader in industrial automation and machinery, has recently unveiled their latest innovation in the field of CNC machinery, the cutting-edge side grooving machine. With this new addition to their product line, [Company Name] aims to revolutionize the manufacturing industry by providing a highly efficient, precise, and reliable solution for various grooving applications.The new CNC side grooving machine is a result of extensive research and development conducted by [Company Name]'s team of skilled engineers and experts in the field of industrial machinery. Designed to meet the increasing demand for precise side grooves in various materials such as metal, wood, plastic, and composite materials, this advanced machine offers unparalleled performance and flexibility.One of the key features of the CNC side grooving machine is its high level of precision. Equipped with state-of-the-art technology, including advanced servo motors and precision ball screws, it ensures that each side groove is perfectly dimensioned and accurately positioned. This level of precision not only improves the overall quality of the final product but also minimizes material wastage, leading to substantial cost savings for manufacturers.Moreover, the CNC side grooving machine boasts a user-friendly interface, making it easily operable even for those who are new to CNC machinery. The intuitive touchscreen display allows operators to easily program and control the machine, making adjustments and fine-tuning settings to achieve the desired grooving specifications effortlessly. Additionally, the machine's advanced software enables seamless integration with existing production lines, thus enhancing productivity and efficiency in manufacturing processes.Safety has been a key consideration in the design and development of this CNC side grooving machine. The machine is equipped with a range of safety features, including emergency stop buttons, protective covers, and sensors that detect any abnormalities or malfunctions. These safety measures ensure the well-being of operators and reduce the risk of accidents in the work environment, making it an ideal choice for companies prioritizing worker safety.The versatility of the CNC side grooving machine is another aspect that sets it apart from its competitors. With customizable options, manufacturers have the flexibility to adjust various parameters such as feed rate, cutting depth, and tooling selection according to their specific requirements. This adaptability makes it suitable for a wide range of applications, including grooving for automotive parts, aerospace components, furniture manufacturing, and architectural woodworking, to name just a few.In terms of productivity, the CNC side grooving machine delivers exceptional results. Its high-speed spindle and rapid tool change system optimize production cycles, ensuring fast and efficient operation. This allows manufacturers to meet tight deadlines and manage high-volume production demands efficiently. Moreover, the machine's robust construction and durable components contribute to its long service life, minimizing downtime for maintenance and repair.With the introduction of the innovative CNC side grooving machine, [Company Name] aims to continue providing cutting-edge solutions that empower manufacturers with enhanced efficiency and productivity. By combining advanced technology, precision engineering, and user-friendly design, this machine is set to become an essential tool for businesses striving for excellence in their manufacturing processes.About [Company Name]:[Company Name] is a globally renowned provider of industrial automation and machinery solutions. With a rich history spanning over [number] years, the company has consistently evolved to cater to the dynamic needs of the manufacturing sector. Whether it is CNC machinery, robotic systems, or other industrial automation equipment, [Company Name] prides itself on delivering innovative and reliable solutions that enable businesses to thrive in today's competitive market.For more information about the CNC side grooving machine and other products offered by [Company Name], please visit [company website].Contact:[Company Name][Contact Person][Title][Phone number][Email address]

Top Trends in Metal Edge Banding for 2022

Metal Edge Banding is an essential component in the manufacturing and construction industry, used to seal and protect the edges of various materials such as wood, metal, and plastic. The use of metal edge banding provides a clean and finished look to the edges of furniture, countertops, and other surfaces, while also increasing durability and longevity. With its wide range of applications, metal edge banding has become a popular choice for architects, designers, and manufacturers looking to enhance the aesthetic appeal and functionality of their products.With a commitment to providing high-quality metal edge banding solutions, {Company Name} has established itself as a leading manufacturer in the industry. The company, with its state-of-the-art production facilities and innovative technologies, has gained a strong reputation for delivering precision-engineered edge banding products that meet the highest standards of quality and performance. Their extensive range of metal edge banding products caters to the diverse needs of their customers, offering a variety of sizes, shapes, and finishes to suit different applications and design requirements.{Company Name} takes pride in its ability to customize metal edge banding solutions to meet the unique specifications of their clients. With a team of skilled engineers and designers, the company can develop custom edge banding solutions that align with the specific design and functional requirements of each project. This flexibility and attention to detail have made {Company Name} a preferred partner for architects, designers, and manufacturers seeking tailor-made metal edge banding solutions for their projects.In addition to its commitment to quality and customization, {Company Name} places a strong emphasis on sustainability and environmental responsibility in its manufacturing processes. The company is dedicated to minimizing its environmental impact by using eco-friendly materials and implementing sustainable production practices. This focus on sustainability has not only earned {Company Name} recognition for its environmental stewardship but has also resonated with customers who prioritize green and sustainable building materials for their projects.Furthermore, {Company Name} maintains a strong focus on innovation, constantly investing in research and development to improve its edge banding products and explore new possibilities in metal edge banding technology. By staying at the forefront of technological advancements, the company remains ahead of the curve in delivering cutting-edge solutions that meet the evolving demands of the market.As part of its commitment to customer satisfaction, {Company Name} provides comprehensive support and guidance to its clients throughout the entire process, from initial consultation to product installation. The company's team of experts offers technical assistance, design recommendations, and project coordination to ensure a seamless experience for its customers. This customer-centric approach has earned {Company Name} a loyal clientele and a strong reputation for reliability and professionalism in the industry.In conclusion, Metal Edge Banding is a crucial component in the manufacturing and construction of various products and surfaces. With its aesthetic and functional benefits, metal edge banding has become an integral part of modern architecture and design. {Company Name} has established itself as a leading manufacturer in the metal edge banding industry, offering high-quality, customizable, and sustainable solutions that meet the diverse needs of its clients. With a focus on innovation, customer satisfaction, and environmental responsibility, {Company Name} continues to set new standards in metal edge banding technology and remains a trusted partner for architects, designers, and manufacturers around the world.

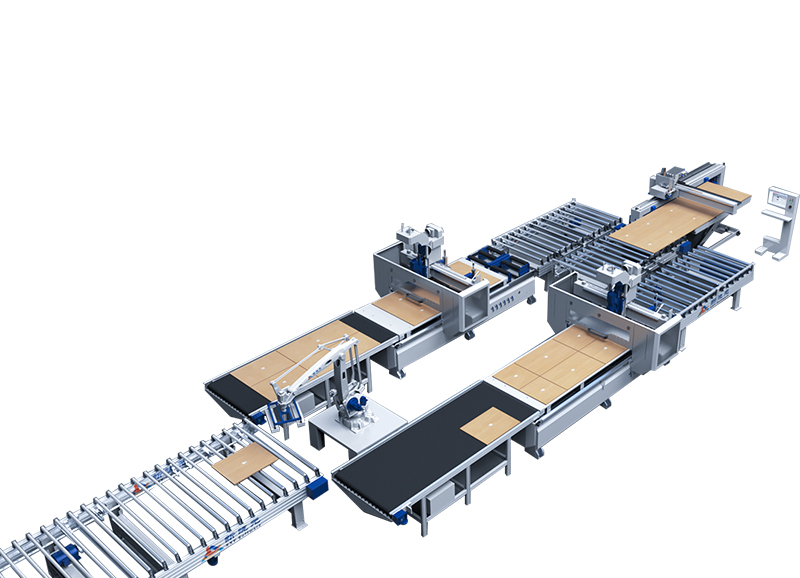

Cabinet Making Machine Production Line: Everything You Need to Know

[Company Name] is proud to announce the launch of their latest Cabinet Making Machine Production Line. This new production line is set to revolutionize the cabinet-making industry with its state-of-the-art technology and unparalleled efficiency.The Cabinet Making Machine Production Line is designed to streamline the manufacturing process, allowing for increased production capacity and higher quality output. The line consists of a series of machines that are specifically designed for different stages of the cabinet-making process, from cutting and shaping the raw materials to assembling and finishing the final product.One of the key features of the Cabinet Making Machine Production Line is its automation capabilities. The machines are equipped with advanced robotics and computerized controls, allowing for precise and consistent production without the need for manual intervention. This not only reduces the margin of error but also significantly speeds up the production process, resulting in a higher output with lower labor costs.In addition to its automation capabilities, the Cabinet Making Machine Production Line also boasts a high level of customization. The machines can be programmed to accommodate various sizes and styles of cabinets, allowing manufacturers to cater to a wide range of customer preferences. This flexibility is crucial for companies that are looking to diversify their product offerings and cater to a broader market.Furthermore, the Cabinet Making Machine Production Line is designed with sustainability in mind. The machines are equipped with energy-efficient components, and the production process is optimized to minimize waste. This not only aligns with [Company Name]'s commitment to environmental responsibility but also presents an opportunity for manufacturers to reduce their carbon footprint and operating costs.The launch of the Cabinet Making Machine Production Line marks a significant milestone for [Company Name], further solidifying its position as a global leader in machinery and manufacturing solutions. With years of experience and expertise in the industry, [Company Name] is dedicated to providing cutting-edge technology and innovative solutions to help businesses thrive in an increasingly competitive market.[Company Name] is renowned for its dedication to quality and customer satisfaction. They offer comprehensive support and training programs to ensure that their clients can fully leverage the capabilities of the Cabinet Making Machine Production Line. From installation and commissioning to ongoing maintenance and technical support, [Company Name] is committed to being a trusted partner for all of its customers' machinery needs.The launch of the Cabinet Making Machine Production Line has already garnered significant attention within the industry, with several manufacturers expressing keen interest in adopting this groundbreaking technology. The potential impact of this production line on the cabinet-making industry is immense, opening up new opportunities for businesses to enhance their productivity and competitiveness.In conclusion, the introduction of the Cabinet Making Machine Production Line by [Company Name] represents a significant advancement in the cabinet-making industry. With its cutting-edge technology, customization capabilities, and commitment to sustainability, this production line is set to redefine the way cabinets are manufactured. As [Company Name] continues to push the boundaries of innovation, it is poised to shape the future of manufacturing for years to come.

The Ultimate 5-in-1 Woodworking Machine for Your DIY Projects

Introducing the 5 In 1 Combination Woodworking Machine from [Company Name], your one-stop solution for all your woodworking needs. The [Company Name] has been a key player in the woodworking machinery industry for over 20 years, providing high-quality and innovative machines to workshops and manufacturing plants around the world. With a strong emphasis on customer satisfaction and product reliability, the [Company Name] has built a solid reputation as a trusted and leading manufacturer in the industry.The new 5 In 1 Combination Woodworking Machine is the latest addition to the [Company Name] product lineup, designed to streamline and optimize the woodworking process. This versatile and compact machine is a game-changer for woodworking enthusiasts and professionals alike, offering a range of functions in one convenient package. Whether you are a seasoned woodworker or just starting out, this machine is sure to enhance your productivity and precision in the workshop.So, what exactly does the 5 In 1 Combination Woodworking Machine offer? Firstly, it combines five essential woodworking functions into one unit, including a table saw, planer, thicknesser, spindle moulder, and mortiser. This means that users can tackle a variety of woodworking tasks without the need for multiple machines, saving both space and time in the workshop. The machine also boasts a powerful motor and precision engineering, ensuring smooth and accurate performance across all its functions.In addition to its functional versatility, the 5 In 1 Combination Woodworking Machine is also designed with user convenience in mind. It features intuitive controls, quick changeover capabilities, and safety features, making it easy and safe to operate for woodworkers of all skill levels. The machine is constructed from durable and high-quality materials, ensuring its longevity and reliability in demanding workshop environments.[Company Name] takes great pride in its commitment to customer satisfaction and support. Alongside the release of the 5 In 1 Combination Woodworking Machine, the company is also rolling out comprehensive training and support programs for users. This includes instructional materials, online resources, and dedicated customer service to assist with any inquiries or technical issues. With [Company Name], customers can have peace of mind knowing that they are supported every step of the way in their woodworking journey.The introduction of the 5 In 1 Combination Woodworking Machine is the result of [Company Name]'s ongoing dedication to innovation and excellence in the woodworking machinery industry. By listening to the needs and feedback of its customers, [Company Name] continues to push the boundaries of what is possible in woodworking technology. The 5 In 1 Combination Woodworking Machine is a testament to this commitment, delivering a solution that empowers woodworkers to work more efficiently and effectively.With its reliable performance, comprehensive support, and industry-leading innovation, the 5 In 1 Combination Woodworking Machine from [Company Name] is set to become an essential tool for woodworking professionals and hobbyists alike. Whether you are looking to expand your woodworking capabilities or streamline your workshop, this machine is sure to exceed your expectations and deliver exceptional results.In conclusion, the 5 In 1 Combination Woodworking Machine from [Company Name] is a game-changing addition to the woodworking industry, offering unparalleled versatility, convenience, and reliability. As [Company Name] continues to set the standard for woodworking machinery, customers can expect nothing but the best from this innovative and customer-focused company.

Mastering Machining with a Drill Press for Precision Results

In the world of precision engineering and manufacturing, the importance of machining processes cannot be overstated. These processes are crucial for creating the intricate parts and components that are used in various industries, from automotive and aerospace to medical and consumer goods. One of the most commonly used machining processes is drilling, and a tool that is synonymous with drilling is the drill press.A drill press is a powerful and versatile tool that can be used for a wide range of drilling applications. It consists of a motor, a spindle, and a drill head, and is designed to precise and accurate holes in a variety of materials, including metal, wood, and plastic. With the right attachments and accessories, a drill press can also be used for other machining operations such as reaming, countersinking, and tapping.{Company Name} is a leading manufacturer of precision machining tools and equipment, with a strong reputation for innovation, quality, and reliability. With a history dating back to over 50 years, {Company Name} has continually pushed the boundaries of what is possible in the field of machining, and has become a trusted partner for companies around the world.Their latest innovation in the field of drilling and machining is the {brand name} series of drill presses. These drill presses are designed to provide unparalleled precision, power, and versatility, making them the ideal choice for a wide range of machining applications. With a robust construction, powerful motor, and a wide range of speed settings, the {brand name} drill press is capable of handling the most demanding drilling tasks with ease.One of the key features of the {brand name} drill press is its versatility. With a range of accessories and attachments available, it can be easily customized to meet the specific needs of different machining applications. Whether it is drilling small, precise holes in delicate components or removing material quickly and efficiently, the {brand name} drill press can handle it all.In addition to its versatility, the {brand name} drill press also offers unmatched precision. With a precise depth stop and adjustable depth scale, it allows for accurate and consistent drilling depths, ensuring that each hole is drilled to the exact specifications. This level of precision is essential in industries where even the smallest deviation can result in costly errors and rework.Furthermore, the {brand name} drill press is also designed with the safety and comfort of the operator in mind. With features such as a safety guard, emergency stop button, and ergonomic handles, it provides a safe and comfortable working environment, reducing the risk of accidents and fatigue.The {brand name} drill press is the culmination of years of research, development, and testing, and is a testament to {Company Name}'s commitment to providing the best possible machining solutions. With its unmatched precision, versatility, and safety features, it is sure to become an essential tool in the arsenal of any precision engineering or manufacturing company.In conclusion, the {brand name} drill press is a game-changer in the field of drilling and machining. Its precision, power, and versatility make it the ideal choice for a wide range of applications, and its safety features ensure a comfortable and secure working environment. Backed by the reputation and expertise of {Company Name}, the {brand name} drill press is set to become the go-to tool for machining professionals around the world.