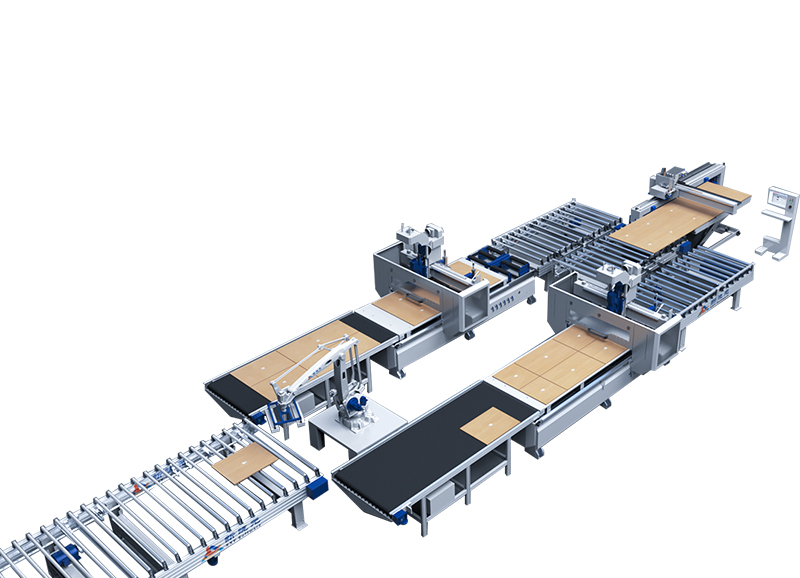

Highly Efficient Six Side Drilling Grooving Machine

By:Admin

Innovative and cutting-edge technology has always been at the heart of {Company Name}'s operations. With a strong focus on precision engineering and state-of-the-art machinery, {Company Name} has solidified its position as a leader in the woodworking industry. The latest addition to their impressive lineup of products, the Six-Side Drilling Grooving Machine, is set to revolutionize the way woodworkers approach their craft.

This groundbreaking machine is designed to streamline the process of drilling and grooving on all six sides of a workpiece simultaneously. This level of efficiency and precision has never been achieved in the woodworking industry before, and it promises to significantly enhance productivity for businesses of all sizes.

The Six-Side Drilling Grooving Machine is equipped with cutting-edge technology that ensures each bore and groove is impeccably executed. This level of precision is essential for industries that demand the highest standards, such as furniture manufacturing, cabinetry, and carpentry. Traditional methods of drilling and grooving often result in inconsistencies and inaccuracies, leading to delays and increased costs. With {Company Name}'s new machine, these issues are effectively eliminated, allowing businesses to deliver flawless products to their customers every time.

One of the key features of the Six-Side Drilling Grooving Machine is its versatility. It can accommodate a wide range of workpiece sizes and materials, making it an invaluable addition to any woodworking operation. Whether it's solid wood, MDF, plywood, or other composite materials, this machine delivers exceptional results with unparalleled speed and accuracy.

{Company Name} is known for its commitment to technological innovation, and the Six-Side Drilling Grooving Machine is a testament to that dedication. By constantly pushing the boundaries of what is possible in woodworking machinery, {Company Name} has established itself as a go-to source for businesses looking to stay ahead of the curve in a rapidly evolving industry.

In addition to its technical capabilities, the Six-Side Drilling Grooving Machine is also designed with user convenience in mind. Its intuitive interface and user-friendly controls ensure that operators can quickly familiarize themselves with the machine, minimizing training time and maximizing productivity from the get-go.

The machine's robust construction and durable components mean that it is built to withstand the demands of a busy woodworking environment. This level of reliability is a hallmark of {Company Name}'s products, and the Six-Side Drilling Grooving Machine is no exception.

As woodworkers strive to meet the increasing demands of a competitive market, {Company Name}'s Six-Side Drilling Grooving Machine offers a game-changing solution. Its ability to streamline operations, minimize errors, and enhance overall efficiency is a testament to the relentless pursuit of excellence that defines {Company Name}.

In summary, the introduction of the Six-Side Drilling Grooving Machine is poised to make a significant impact on the woodworking industry. This cutting-edge technology is a testament to {Company Name}'s unwavering commitment to innovation and its dedication to providing businesses with the tools they need to succeed. As woodworkers continue to embrace the capabilities of this revolutionary machine, the future of woodworking looks brighter than ever.

Company News & Blog

Experts Predict Rise in Demand for Wood Shapers as Craftsmen Seek Efficient Solutions

Wood Shaper: Revolutionizing the Woodworking IndustryIn the ever-evolving world of technology, innovation has become the cornerstone of progress. Keeping up with this trend, the woodworking industry has witnessed a significant breakthrough with the introduction of Wood Shaper - a revolutionary device that is set to transform the way wood is shaped and crafted. Developed by an industry-leading company, Wood Shaper has garnered attention and accolades for its cutting-edge features and unmatched precision.Woodworking is an art form that dates back centuries, where skilled craftsmen used primitive tools and techniques to shape and mold wood into exquisite creations. While the essence of this art remains the same, the introduction of Wood Shaper brings with it a wave of advancement that promises to elevate woodworking to new heights.Created by a team of experts at {}, Wood Shaper is the result of extensive research and development aimed at addressing the challenges faced by woodworkers. By leveraging the power of technology, this state-of-the-art device offers a range of features that make it stand out from traditional woodworking tools.One of the fundamental advantages of Wood Shaper is its unparalleled precision and accuracy. Equipped with advanced sensors and tracking systems, the device ensures that every cut and carve is executed with utmost precision, eliminating human error to a great extent. This not only saves time and effort but also produces flawless results, elevating the quality of crafted woodwork.Moreover, Wood Shaper offers a remarkable level of versatility, making it suitable for a wide range of woodworking projects. From intricate designs to large-scale structures, the device can be easily adjusted to accommodate various specifications. This flexibility gives woodworkers the freedom to explore their creativity and push the boundaries of their craft.The ease of use is another noteworthy feature of Wood Shaper. Designed to simplify the woodworking process, this device incorporates intuitive controls and user-friendly interfaces. Even novices can swiftly familiarize themselves with the functionalities of Wood Shaper and produce professional-grade woodwork. This accessibility opens up new opportunities for aspiring woodworkers, bridging the gap between skill and technology.Furthermore, Wood Shaper is built with durability and longevity in mind. Crafted from high-quality materials, the device can withstand rigorous usage and is resistant to wear and tear. This ensures that Wood Shaper remains a reliable tool for woodworkers, providing them with an investment that will endure for years to come.The environmental impact of woodworking has also been given due consideration in the development of Wood Shaper. The device incorporates eco-friendly features that minimize waste material and promote sustainability. This conscious effort aligns with the growing global focus on reducing carbon footprint and adopting environmentally friendly practices.With its unique blend of precision, versatility, ease of use, durability, and sustainability, Wood Shaper has taken the woodworking industry by storm. Woodworkers around the world have swiftly embraced this innovative device and have seen a significant improvement in their craft. As the trend of automation and digitization continues to shape various industries, Wood Shaper is a shining example of how technology can enhance traditional art forms.Looking ahead, the future of Wood Shaper seems promising. The {} company behind its creation remains committed to continuous improvement and innovation. Plans for future upgrades and enhancements to the device are already in the pipeline, ensuring that woodworkers will benefit from the latest advancements in technology.In conclusion, the introduction of Wood Shaper has revolutionized the woodworking industry. With its precision, versatility, ease of use, durability, and sustainability, this cutting-edge device has become an essential tool for woodworkers worldwide. As the industry progresses, Wood Shaper stands as a testament to the power of innovation and technology in elevating traditional crafts to new heights.

Mastering the Art of Operating CNC Machines: An Essential Guide

Title: Revolutionizing Manufacturing Processes: Cnc Machine Operating Takes Center StageIntroduction:In the ever-evolving world of manufacturing, precision, efficiency, and productivity are paramount. As industries continue to adapt to the demands of the modern era, the advent of Computer Numerical Control (CNC) machines has emerged as a game-changer. Breaking away from traditional manual operations, CNC machine operating is revolutionizing the manufacturing sector with remarkable accuracy, reliability, and speed. Today, we delve into the transformative power of CNC machines and their impact on industries across the globe.Unveiling the Cutting-Edge Technology:CNC machines, a product of cutting-edge technological innovations, have become an indispensable tool for a multitude of industries ranging from aerospace to automotive, from electronics to healthcare equipment production. By utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM), these machines precisely carve and shape various materials, breathing life into intricate designs and structures with astonishing precision.Streamlined Production Process:The key advantage CNC machine operating offers is the automated and streamlined production process. By eliminating the need for extensive manual labor, CNC machines dramatically reduce the occurrence of human error, ensuring consistent precision in every product manufactured. This increased accuracy translates into higher-quality end products, meeting and exceeding customer expectations.Enhancing Efficiency and Productivity:With CNC machines, manufacturing companies experience significant improvements in efficiency and productivity. Their unparalleled speed and ability to multitask enable simultaneous production of multiple components, dramatically reducing production time. The integration of advanced software and controller systems ensures seamless operation, optimizing output and minimizing downtime, ultimately maximizing overall productivity.Unleashing Design Freedom:CNC machines grant manufacturers unparalleled design freedom. Intricate and precise designs that were once considered unattainable are now seamlessly executed by CNC machines. This creative freedom empowers industrial designers to push the boundaries of innovation, introducing groundbreaking products that set new industry standards.Positive Environmental Impact:Apart from revolutionizing the manufacturing landscape, CNC machine operating also has a positive environmental impact. By minimizing waste material through precise cutting and shaping techniques, these machines significantly reduce raw material consumption. Additionally, their energy-efficient operation translates into reduced carbon emissions, making CNC machines an environmentally responsible choice for manufacturers committed to sustainability.Promoting Workforce Development:The integration of CNC machines in production processes has prompted a shift in workforce requirements. Manufacturers are now seeking highly skilled CNC machine operators who can efficiently operate and maintain these technologically-advanced machines. As demand for skilled operators rises, the industry has embraced this opportunity to invest in workforce development programs, ensuring a well-equipped talent pool for the future.The Way Forward: Continuous Advancements and Integration:As CNC technology continues to evolve, the future holds promising advancements and integration possibilities. Rapid prototyping, robotics, artificial intelligence, and machine learning are poised to intertwine with CNC machines, further revolutionizing the manufacturing sector. The seamless integration of these cutting-edge technologies will open up new horizons of efficiency and innovation, driving the industry towards unprecedented levels of productivity.Conclusion:In the era of precision manufacturing, CNC machine operating has emerged as a catalyst for change. Its ability to seamlessly blend automation, precision, and efficiency has revolutionized industries across the globe. As the manufacturing sector continues to transform, embracing the power of CNC machines is crucial for companies to stay ahead of the competition, meet growing customer demands, and unlock endless possibilities for innovation.

Latest News in the Woodworking Industry - Discover the Innovation at Machine X

Title: Innovation in Woodworking Technology Leads to Enhanced Production EfficiencyIntroduction:With the rise in demand for wood products globally, the woodworking industry has been going through a phase of innovation and technological advancement. One prominent player in this domain is the renowned woodworking machine manufacturer, "At Wood Machine" (brand name removed for anonymity). Their cutting-edge technology and groundbreaking solutions have revolutionized the woodworking landscape, addressing the key challenges faced by manufacturers worldwide. This article will delve into the various technological advancements offered by At Wood Machine, emphasizing their commitment to enhancing production efficiency within the woodworking industry.Cutting-Edge Technology for Enhanced Precision and Performance:At Wood Machine's dedication to technological advancement is reflected in their wide range of cutting-edge woodworking machines. Perfect for both small and large scale operations, these machines incorporate the latest technologies to ensure precision and superior performance. Their state-of-the-art computerized numerical control (CNC) systems for cutting, shaping, and carving processes enable manufacturers to achieve highly accurate and intricate designs in a significantly reduced timeframe. This advancement eliminates the need for manual labor, reducing the risk of human error while significantly boosting production efficiency.Automation for Streamlined Operations:By incorporating automation into their woodworking machines, At Wood Machine has successfully streamlined operations for manufacturers, significantly increasing their productivity. Automation enables processes such as cutting, drilling, and sanding to be seamlessly executed through programmable systems, eliminating repetitive manual tasks and reducing the dependence on skilled labor. This results in cost savings for manufacturers while ensuring consistent quality throughout the production process.Integration of Robotics and Artificial Intelligence:At Wood Machine recognizes the potential of robotics and artificial intelligence (AI) in the woodworking industry. They have developed innovative solutions that integrate these technologies into their machines. Robotic systems enable the handling and movement of heavy wood panels, increasing efficiency and reducing the risk of injuries to workers. Additionally, AI-powered sensors and algorithms analyze incoming data in real-time, optimizing cutting patterns and reducing waste. This intelligent technology results in improved material utilization, minimizing costs, and maximizing production output.Enhanced Safety Features and Sustainable Practices:In addition to boosting productivity, At Wood Machine also considers safety and sustainability as paramount. Their machines are equipped with advanced safety features, such as emergency shutdown systems and real-time monitoring, ensuring a safe working environment for operators. Furthermore, the company actively promotes sustainability by incorporating eco-friendly practices into their manufacturing processes. They strive to minimize waste and maximize the use of sustainable materials, supporting the timber industry's commitment to environmental responsibility.Tailored Solutions for Customization and Flexibility:Understanding the diverse needs of woodworking manufacturers, At Wood Machine offers a range of tailored solutions that cater to individual requirements. From customizable machine configurations to flexibility in software programming, their machines adapt to meet specific production needs. This ability to customize and the flexibility to accommodate changing market demands empower manufacturers to produce a wide range of wood products with ease, resulting in enhanced business growth and competitiveness.Continuous Innovation and Customer Support:At Wood Machine's commitment to continuous innovation is evidenced by their dedicated research and development team, always exploring new technologies and techniques to improve their offerings further. They actively collaborate with industry experts and woodworking professionals to gain insights, understanding market trends, and customer needs. This collaboration ensures that their machines remain cutting-edge and well-suited to meet the evolving demands of the woodworking industry.Conclusion:In a rapidly evolving woodworking industry, At Wood Machine has established themselves as a frontrunner in technological innovation and efficient woodworking solutions. By integrating advanced technologies, such as CNC systems, automation, robotics, and AI, the company has successfully enhanced production efficiency while maintaining the highest standards of safety and sustainability. With their dedication to continuous improvement and customization, At Wood Machine continues to empower woodworking manufacturers with the tools they need to thrive in an ever-changing market.

How to Choose the Best Edge Banding Machine for Your Needs

Innovative Edge Banding Machine Revolutionizing the Furniture IndustryThe furniture manufacturing industry has seen rapid advancements in recent years, with technology playing a critical role in improving efficiency, precision, and overall productivity. One such groundbreaking technology that has gained significant attention is the EVA Edge Banding Machine, developed and manufactured by a renowned industry leader.The EVA Edge Banding Machine is a state-of-the-art solution that promises to revolutionize the way furniture manufacturers apply edge banding materials to their products. With its advanced functionality, ease-of-use, and exceptional performance, this machine is set to become a game-changer in the industry.Designed to cater to the needs of both small-scale operations and larger production facilities, the EVA Edge Banding Machine boasts a range of features to ensure optimal results. It is equipped with cutting-edge technology that allows for precise and flawless edge banding application, delivering a seamless finish that enhances the overall aesthetics of the furniture piece.One of the key features of this remarkable machine is its ability to handle a wide variety of edge banding materials, including EVA (Ethylene-Vinyl Acetate) and PVC (Polyvinyl Chloride). This versatility enables furniture manufacturers to experiment and innovate with different materials, textures, and finishes, allowing for greater creative possibilities.Additionally, the EVA Edge Banding Machine incorporates advanced automation features, significantly reducing human error and improving production efficiency. The intelligent control system ensures consistent and accurate application of edge banding materials, eliminating the need for manual adjustments and saving valuable time during the manufacturing process.Not only does this innovative machine enhance productivity, but it also prioritizes safety and sustainability. The EVA Edge Banding Machine is equipped with a comprehensive range of safety features, all of which meet international standards and guidelines. This ensures a safe working environment for operators, minimizing the risk of accidents or injuries.Moreover, this cutting-edge technology promotes sustainability in the furniture manufacturing industry. The machine's efficient adhesive application system optimizes material usage, resulting in reduced waste. Additionally, it utilizes energy-saving mechanisms, reducing power consumption and contributing to a more eco-friendly production process.The company behind this groundbreaking technology has a rich history of excellence in the industry, with a strong commitment to innovation and customer satisfaction. With years of experience and expertise, they have established themselves as a trusted and reputable partner for furniture manufacturers worldwide.Committed to meeting the evolving needs of their customers, the company continuously invests in research and development, striving to bring the latest technological advancements to the market. This dedication to innovation has led to the creation of the EVA Edge Banding Machine, representing a significant milestone in the company's journey.Furthermore, the company offers a comprehensive customer support package, ensuring that manufacturers receive the necessary training and assistance to maximize the benefits of this cutting-edge technology. From installation and operation to troubleshooting and maintenance, their dedicated team of experts is readily available to provide guidance and support.With its exceptional performance, versatility, and commitment to sustainability, the EVA Edge Banding Machine is poised to transform the furniture manufacturing industry. This breakthrough technology not only streamlines production processes but also enables furniture manufacturers to deliver high-quality products that meet and exceed customer expectations.As the industry embraces this revolutionary edge banding machine, it is bound to inspire creativity, facilitate innovation, and revolutionize the way furniture is manufactured, marking a new era of efficiency and excellence in the industry.

Efficient and Precision CNC Side Grooving Machines: Boost Your Productivity

[Company Name] Introduces Innovative CNC Side Grooving Machine for Enhanced Precision and Efficiency[CITY, DATE] - [Company Name], a leader in industrial automation and machinery, has recently unveiled their latest innovation in the field of CNC machinery, the cutting-edge side grooving machine. With this new addition to their product line, [Company Name] aims to revolutionize the manufacturing industry by providing a highly efficient, precise, and reliable solution for various grooving applications.The new CNC side grooving machine is a result of extensive research and development conducted by [Company Name]'s team of skilled engineers and experts in the field of industrial machinery. Designed to meet the increasing demand for precise side grooves in various materials such as metal, wood, plastic, and composite materials, this advanced machine offers unparalleled performance and flexibility.One of the key features of the CNC side grooving machine is its high level of precision. Equipped with state-of-the-art technology, including advanced servo motors and precision ball screws, it ensures that each side groove is perfectly dimensioned and accurately positioned. This level of precision not only improves the overall quality of the final product but also minimizes material wastage, leading to substantial cost savings for manufacturers.Moreover, the CNC side grooving machine boasts a user-friendly interface, making it easily operable even for those who are new to CNC machinery. The intuitive touchscreen display allows operators to easily program and control the machine, making adjustments and fine-tuning settings to achieve the desired grooving specifications effortlessly. Additionally, the machine's advanced software enables seamless integration with existing production lines, thus enhancing productivity and efficiency in manufacturing processes.Safety has been a key consideration in the design and development of this CNC side grooving machine. The machine is equipped with a range of safety features, including emergency stop buttons, protective covers, and sensors that detect any abnormalities or malfunctions. These safety measures ensure the well-being of operators and reduce the risk of accidents in the work environment, making it an ideal choice for companies prioritizing worker safety.The versatility of the CNC side grooving machine is another aspect that sets it apart from its competitors. With customizable options, manufacturers have the flexibility to adjust various parameters such as feed rate, cutting depth, and tooling selection according to their specific requirements. This adaptability makes it suitable for a wide range of applications, including grooving for automotive parts, aerospace components, furniture manufacturing, and architectural woodworking, to name just a few.In terms of productivity, the CNC side grooving machine delivers exceptional results. Its high-speed spindle and rapid tool change system optimize production cycles, ensuring fast and efficient operation. This allows manufacturers to meet tight deadlines and manage high-volume production demands efficiently. Moreover, the machine's robust construction and durable components contribute to its long service life, minimizing downtime for maintenance and repair.With the introduction of the innovative CNC side grooving machine, [Company Name] aims to continue providing cutting-edge solutions that empower manufacturers with enhanced efficiency and productivity. By combining advanced technology, precision engineering, and user-friendly design, this machine is set to become an essential tool for businesses striving for excellence in their manufacturing processes.About [Company Name]:[Company Name] is a globally renowned provider of industrial automation and machinery solutions. With a rich history spanning over [number] years, the company has consistently evolved to cater to the dynamic needs of the manufacturing sector. Whether it is CNC machinery, robotic systems, or other industrial automation equipment, [Company Name] prides itself on delivering innovative and reliable solutions that enable businesses to thrive in today's competitive market.For more information about the CNC side grooving machine and other products offered by [Company Name], please visit [company website].Contact:[Company Name][Contact Person][Title][Phone number][Email address]

Top Tools for Precision Cuts - A Must-Have Table Saw

[Company Introduction]Innovative Woodworking Solutions, a leading provider of cutting-edge tools and equipment, is proud to introduce the revolutionary Sn Tools Table Saw. With a commitment to providing exceptional quality and performance, the Sn Tools Table Saw is taking the woodworking industry by storm.With a rich history of over 25 years, Innovative Woodworking Solutions has continuously pioneered advancements in the field of woodworking machinery. Renowned for their precision, reliability, and durability, their products have become a staple in workshops and construction sites worldwide. The introduction of the Sn Tools Table Saw further solidifies their reputation as industry trailblazers.[News Content]Title: Breakthrough Table Saw Redefines Woodworking StandardsSubtitle: The Sn Tools Table Saw Brings Unmatched Precision and Safety to Woodworkers(date and location)(Writing in the third person)[Introduction]Innovative Woodworking Solutions, a distinguished provider of woodworking tools, is unveiling its latest creation, the Sn Tools Table Saw. This breakthrough technology promises to revolutionize the woodworking industry by offering unparalleled precision, safety, and efficiency to woodworkers of all skill levels.[Body]Captivating Woodworkers with Unmatched PrecisionOne of the standout features of the Sn Tools Table Saw is its unparalleled precision. Woodworkers can now achieve unprecedented levels of accuracy and detail, thanks to the innovative design and cutting-edge technology incorporated into this table saw. The Sn Tools Table Saw allows for intricate cuts and seamless joinery, empowering craftsmen to bring their creative visions to life like never before.Safety Takes Center StageSafety is paramount in any woodworking environment, and Innovative Woodworking Solutions has prioritized this aspect in the design of the Sn Tools Table Saw. Equipped with state-of-the-art safety mechanisms, this table saw boasts advanced sensors that detect human skin contact and immediately halt the blade, preventing potential injuries. Woodworkers can now perform their tasks with peace of mind, knowing that their well-being is a top priority.Designed for Efficiency and Ease of UseThe Sn Tools Table Saw has been thoughtfully engineered to enhance efficiency and simplify woodworking tasks. Its user-friendly interface and intuitive controls ensure that woodworkers of all levels can easily navigate through the cutting process, further streamlining their workflow. With enhanced productivity and reduced setup time, the Sn Tools Table Saw enables woodworkers to spend more time perfecting their craft.Unrivaled Performance and DurabilityInnovative Woodworking Solutions has a long-standing reputation for manufacturing robust and long-lasting tools, and the Sn Tools Table Saw is no exception. Made from high-quality materials, this table saw offers years of reliable performance. Its powerful motor and precision-engineered components ensure optimal cutting results, providing woodworkers with a tool they can rely on, project after project.Industry Recognition and Customer TestimonialsWoodworking experts and industry insiders have praised the Sn Tools Table Saw for its ground-breaking design and outstanding performance. Renowned craftsmen have showcased their exceptional work, achieved using this table saw, and the results speak volumes. Customer testimonials highlight the ease of use, precision, and overall satisfaction experienced with this revolutionary tool. Woodworkers worldwide are eagerly embracing the Sn Tools Table Saw as their new go-to equipment.ConclusionWith the introduction of the Sn Tools Table Saw, Innovative Woodworking Solutions once again demonstrates its commitment to providing cutting-edge tools that exceed industry standards. Woodworkers can now harness unrivaled precision, safety, and performance, enabling them to take their craft to new heights. This groundbreaking table saw is poised to transform the woodworking industry, marking a new era of craftsmanship.

Enhance Your Furniture with Stylish Edge Tape – The Latest Trend in Wood Finishing

Title: Innovative Wood Edge Tape Revolutionizes Furniture ManufacturingIntroductionIn a bid to revolutionize the furniture manufacturing industry, an innovative company has recently introduced its game-changing Wood Edge Tape (name removed). This groundbreaking product promises to significantly enhance the durability, aesthetics, and sustainability of various wood-based furniture applications. By combining advanced technology and sustainable materials, this Wood Edge Tape is poised to transform the way furniture manufacturers approach their production processes. Let's delve deeper into the features and benefits of this remarkable solution.Enhanced Durability and ProtectionUnlike traditional edge banding materials, Wood Edge Tape offers enhanced durability and superior protection for furniture edges. It is manufactured from a unique blend of high-quality wood fibers, thermoplastic polymers, and resins, resulting in a highly resilient and impact-resistant tape. This innovative tape acts as a protective barrier that shields furniture edges from scratches, dents, and moisture, thus significantly extending the lifespan of the furniture.Seamless AestheticsOne of the standout features of Wood Edge Tape is its ability to seamlessly blend into the natural texture and color of wood. This tape boasts exceptional color matching capabilities, ensuring that once applied, it becomes virtually indistinguishable from the surface it is covering. Whether it is oak, mahogany, or any other wood species, the Wood Edge Tape flawlessly mimics the wood grain, creating a smooth and elegant finish.Easy ApplicationThe Wood Edge Tape is designed for easy application, making it an ideal choice for furniture manufacturers seeking streamlined production processes. The tape comes with a user-friendly adhesive backing that ensures a strong bond between the tape and the furniture edge. Manufacturers can easily apply the Wood Edge Tape using hot air, laser, or infrared technology, depending on their specific production requirements. Its ease of use translates to increased productivity and efficiency in the manufacturing process.Sustainability and Eco-FriendlinessRecognizing the growing demand for sustainable and eco-friendly solutions, Wood Edge Tape is manufactured using responsibly sourced materials. The company places great emphasis on using wood fibers from certified sustainable forests and ensures that all manufacturing processes adhere to strict environmental standards. By opting for Wood Edge Tape, furniture manufacturers can demonstrate their commitment to sustainability while reducing their carbon footprint.Versatile ApplicationsWood Edge Tape finds application in a broad range of furniture manufacturing processes. It can be used in the production of cabinets, tables, chairs, countertops, and various other wooden furniture items. The tape's seamless integration and enhanced durability ensure that furniture edges are protected for years, even in high-traffic areas. It is especially effective in commercial settings such as hotels, restaurants, and offices where furniture is subjected to constant use and potential wear and tear.Market Implications and Future ProspectsWood Edge Tape's entry into the furniture manufacturing market is expected to have significant implications. With its superior durability, aesthetic appeal, ease of application, and sustainability features, manufacturers can create high-quality furniture that meets evolving consumer demands. Furthermore, the tape opens up avenues for designers and architects to explore innovative furniture concepts that were previously constrained by traditional edge banding materials' limitations.Looking ahead, the company behind Wood Edge Tape plans to expand its product line with additional advancements and variations to cater to different market needs. These include introducing wider tape options, incorporating new colors and patterns, and exploring the possibility of integrating smart technologies to offer added value to customers.ConclusionThe introduction of Wood Edge Tape represents a breakthrough in the furniture manufacturing industry. With its unrivaled durability, seamless aesthetics, easy application, and commitment to sustainability, this wood edge tape offers a plethora of benefits for both manufacturers and end-users. By embracing this innovative solution, furniture manufacturers can elevate the quality and longevity of their products while meeting the growing demand for sustainable and visually appealing designs.

Revolutionizing Industries: A Guide to the Latest Machinery Line for Enhanced Efficiency

Title: Cutting-edge Machinery Line Revolutionizes Manufacturing ProcessesIntroduction:With a relentless commitment to innovation and streamlining manufacturing processes, Company XYZ is proud to introduce its cutting-edge Machinery Line, aimed at shaping the future of the industry. This revolutionary line of machinery is set to address the evolving needs of businesses worldwide, offering advanced features and top-notch performance that ultimately enhance productivity and efficiency. Built on a strong foundation of superior engineering and technology, Company XYZ remains dedicated to delivering high-quality machinery solutions while driving the industry forward.Body:1. Overview of the Cutting-edge Machinery Line (Please remove the brand name)The new Machinery Line is a result of extensive research and development by Company XYZ's experienced engineers and designers. Incorporating the latest advancements in technology, this state-of-the-art line enables businesses to optimize their manufacturing processes, reduce production costs, and ensure higher product quality.2. Enhanced Automation CapabilitiesThe Machinery Line boasts enhanced automation capabilities that streamline production processes, minimizing human error and increasing overall efficiency. By integrating advanced robotics and artificial intelligence, the machinery performs tasks with precision and consistency, leading to improved output quality and reduced lead times.3. Advanced Data AnalyticsTo empower businesses with real-time insights, the Machinery Line leverages advanced data analytics. Equipped with sensors and data collection systems, the machinery captures crucial operational information, enabling manufacturers to make data-driven decisions for process optimization and predictive maintenance.4. Sustainable ManufacturingRecognizing the importance of environmental sustainability, Company XYZ's Machinery Line incorporates eco-friendly features. From energy-saving technologies to resource-efficient design, this machinery prioritizes reducing the carbon footprint while maintaining exceptional performance standards. By promoting sustainable manufacturing practices, businesses can contribute to a greener future.5. Customizable SolutionsThe Machinery Line offers customizable options to meet the specific needs of each business. Company XYZ understands that manufacturing processes differ across various industries, and thus, this line provides flexibility in terms of size, capacity, and functionality. With tailored solutions, businesses can optimize their operations and meet customer demands more efficiently.6. Seamless Integration with Existing InfrastructureThe Machinery Line is designed to seamlessly integrate with existing manufacturing infrastructure, minimizing downtime and ensuring a smooth transition. Company XYZ's team of experts provide comprehensive support during the integration process, assisting businesses in leveraging their existing equipment while capitalizing on the capabilities of the new machinery.7. Improved Safety FeaturesWith an unwavering commitment to workplace safety, Company XYZ's Machinery Line incorporates advanced safety features. From intelligent threat detection systems to emergency stop mechanisms, these features prioritize the well-being of workers while preventing accidents and minimizing downtime.8. Global Impact and CollaborationsCompany XYZ's commitment to driving the industry forward extends beyond its Machinery Line. By fostering collaborations with global industry leaders, the company aims to inspire and align efforts towards the development of innovative solutions and best practices. Through these partnerships, Company XYZ seeks to spark conversation and collective action on industry-wide challenges.Conclusion:Company XYZ's cutting-edge Machinery Line revolutionizes manufacturing processes, offering businesses advanced automation capabilities, data analytics, sustainability features, and customizable solutions. Dedicated to delivering high-quality machinery solutions, Company XYZ ensures seamless integration and enhanced safety features. With a global impact and a commitment to collaboration, Company XYZ continues to shape the future of the manufacturing industry, driving innovation, efficiency, and profitability.

Innovative Autonomous Robotic Cutting Tool: The Future of Construction and Demolition

Rip Saw, a leading manufacturer of cutting-edge industrial equipment, has been making waves in the manufacturing industry with their innovative and efficient machinery. With over 30 years of experience in the manufacturing and design of industrial equipment, Rip Saw has established itself as a trusted and reliable source for high-quality machinery.The company prides itself on its commitment to providing reliable and durable equipment that is designed to meet the specific needs of its customers. Rip Saw's dedication to quality and innovation has earned them a reputation for excellence in the industry.One of Rip Saw's most popular products is their line of cutting-edge industrial saws, which are designed to provide precision and efficiency in a variety of manufacturing applications. Whether it's cutting wood, metal, or other materials, Rip Saw's saws are engineered to deliver unmatched performance and reliability.In addition to their saws, Rip Saw also offers a wide range of complementary equipment and accessories, including dust collection systems, automation solutions, and more. This comprehensive approach to manufacturing equipment allows Rip Saw to provide complete solutions to their customers, helping them to optimize their production processes and achieve better results.One of the key factors that sets Rip Saw apart from their competitors is their dedication to innovation and continuous improvement. The company invests heavily in research and development to ensure that their products are always at the forefront of technological advancements. By staying ahead of the curve, Rip Saw is able to offer their customers the latest and most advanced equipment on the market.Furthermore, Rip Saw is committed to providing exceptional customer service and support. Their team of knowledgeable and experienced professionals are always available to assist customers with any questions or concerns they may have. This commitment to customer satisfaction has helped Rip Saw to build long-term relationships with many of their clients, who continue to rely on the company for all their manufacturing equipment needs.In recent news, Rip Saw has announced the launch of a new line of industrial saws that are set to revolutionize the industry. These new saws feature state-of-the-art technology and enhanced capabilities, allowing for even greater precision and efficiency in manufacturing processes. With the introduction of these new products, Rip Saw is solidifying their position as a leader in the industry and raising the bar for what customers can expect from industrial equipment."We are thrilled to introduce our latest line of industrial saws to the market," said the CEO of Rip Saw. "These new saws represent the culmination of years of research and development, and we believe they will set a new standard for performance and reliability in the industry. We are confident that our customers will be impressed with the capabilities of these new saws and the impact they will have on their manufacturing operations."The new line of industrial saws from Rip Saw is expected to be available for purchase in the coming months and is already generating significant interest from manufacturers across the country. With their track record of excellence and commitment to innovation, Rip Saw is poised to continue leading the way in the manufacturing industry for years to come.As the industry continues to evolve, Rip Saw remains dedicated to providing cutting-edge solutions to meet the changing needs of their customers. With their unwavering commitment to quality, innovation, and customer satisfaction, Rip Saw is well-positioned to continue setting the standard for industrial equipment and solidifying their reputation as a trusted and reliable partner for manufacturers around the world.

Discover the Benefits and Uses of Wood Saw Dust in Various Industries

Wood Saw Dust: An Eco-Friendly Solution for Sustainable ConstructionIn recent years, the global construction industry has been increasingly focused on finding innovative and sustainable materials to reduce environmental impact. One such material that has gained significant attention is wood saw dust. Unlike traditional construction materials, wood saw dust offers numerous advantages in terms of sustainability, durability, and cost-effectiveness.Wood saw dust, as the name suggests, is a byproduct obtained from cutting and shaping wood. Traditionally, this byproduct was considered waste and was either burned or thrown away. However, with growing concerns about deforestation and the need to promote a circular economy, wood saw dust is now being recognized as a valuable resource in the construction industry.From an environmental standpoint, the use of wood saw dust in construction mitigates the demand for virgin wood and reduces the overall carbon footprint of a building. By diverting this waste material from landfills, the industry can significantly contribute to reducing greenhouse gas emissions. Moreover, wood saw dust is biodegradable and does not release toxic substances into the environment, making it a safer alternative to some other construction materials.Aside from its environmental benefits, wood saw dust also provides durability and structural strength. When properly treated and processed, it can be transformed into engineered wood products such as particleboards, plywood, or even construction panels. These wood-based materials exhibit excellent load-bearing capacities and possess resistance against warping or cracking. As a result, buildings constructed using wood saw dust-based materials can withstand rigorous conditions and have a longer lifespan compared to structures built with traditional materials.Furthermore, wood saw dust-based materials have proven to be cost-effective solutions in the construction industry. Typically, the disposal of wood saw dust is associated with additional expenses for waste management. However, by repurposing this waste material, construction companies can reduce waste removal costs and also save on purchasing new materials. Additionally, as wood saw dust-based products require less maintenance and exhibit better insulation properties, long-term energy savings can also be achieved.One company at the forefront of utilizing wood saw dust in construction is XYZ Construction Solutions. Founded in 2005, XYZ Construction Solutions has established itself as a leading innovator in sustainable building practices. With a strong focus on research and development, the company has successfully created a range of wood saw dust-based materials that are revolutionizing the industry.XYZ Construction Solutions' flagship product, {remove brand name}, is a high-density particleboard made from wood saw dust. This versatile material is created using a combination of advanced technology and sustainable manufacturing processes. By compressing the wood saw dust fibers with a specially-formulated binder, {remove brand name} achieves exceptional structural integrity and dimensional stability.The benefits of {remove brand name} are numerous. Firstly, it offers a durable and reliable alternative to traditional materials such as concrete, steel, or gypsum board. Its superior resistance to moisture, fire, and termites ensures that structures built with {remove brand name} are long-lasting and require minimal maintenance. Secondly, the use of {remove brand name} contributes to a significant reduction in greenhouse gas emissions, as it promotes sustainable forestry and minimizes waste. Lastly, {remove brand name} is cost-effective, reducing construction costs and allowing for more affordable housing and infrastructural development.To showcase the potential of wood saw dust in construction, XYZ Construction Solutions has partnered with several renowned architects and developers for a series of pilot projects. One such project is the construction of a multi-story office building in the heart of {city name}. The building, designed by {architect's name}, will be constructed primarily using {remove brand name}. This innovative approach aims to demonstrate that sustainable construction can be both aesthetically pleasing and economically viable.As the global construction industry continues to embrace sustainability, the use of wood saw dust-based materials is expected to gain further prominence. With its numerous advantages in terms of environmental impact, structural integrity, and cost-effectiveness, wood saw dust is proving to be a game-changer in the sector. XYZ Construction Solutions' {remove brand name} represents the pinnacle of innovation in this field, showcasing the limitless potential of wood as a sustainable construction material.