How an Edge Banding Machine Can Streamline Your Woodworking Process

By:Admin

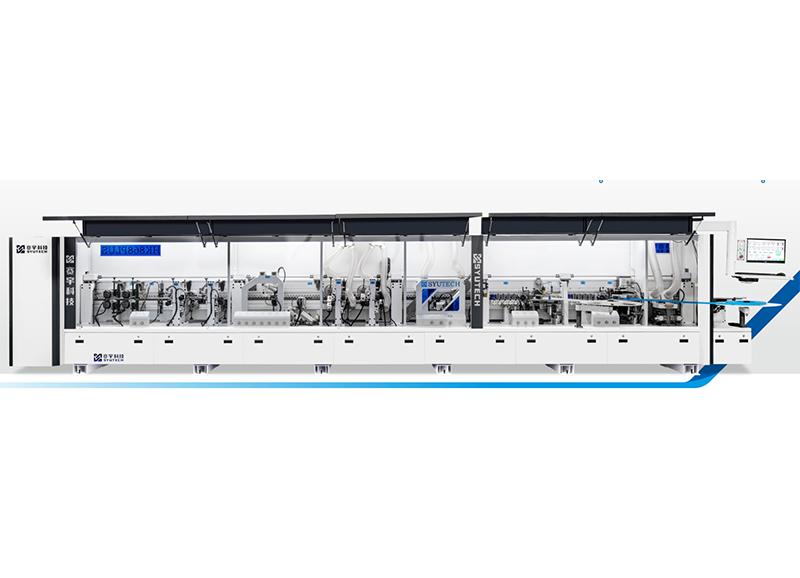

In the ever-evolving world of woodworking machinery, one company has been at the forefront of innovation and efficiency. With their latest release of the EVA edge banding machine, they have once again set a new standard for the industry.

The EVA edge banding machine is a high-tech, fully automated machine that is designed to apply edge banding to a variety of wood-based materials. This machine is equipped with state-of-the-art technology that allows for precise application of edge banding, resulting in a seamless finish that is both durable and aesthetically pleasing.

One of the key features of the EVA edge banding machine is its ability to handle a wide range of edge banding materials, including EVA, PVC, and wood veneer. This versatility makes it an ideal solution for woodworking companies that work with different types of materials. Additionally, the machine is equipped with advanced adhesive systems that ensure a strong and long-lasting bond between the edge banding and the material.

Furthermore, the EVA edge banding machine is designed with efficiency in mind. Its fully automated operation reduces the need for manual labor, which not only saves time but also minimizes the risk of errors. This allows woodworking companies to increase their production output while maintaining a high level of quality.

The company behind the EVA edge banding machine has a long history of providing cutting-edge solutions for the woodworking industry. With over 20 years of experience, they have built a reputation for delivering reliable, high-quality machinery that meets the needs of their clients.

Their commitment to innovation and customer satisfaction has earned them a loyal customer base and a strong presence in the global market. They are known for their dedication to research and development, constantly striving to improve their products and stay ahead of the competition.

In addition to the EVA edge banding machine, the company offers a wide range of woodworking machinery, including panel saws, edge banding machines, CNC routers, and sanding machines. They take pride in their ability to provide comprehensive solutions for woodworking companies of all sizes, from small workshops to large-scale production facilities.

Another key aspect of the company's success is their focus on customer support and service. They understand the importance of providing reliable technical assistance and spare parts availability to ensure that their clients' operations run smoothly at all times.

Looking ahead, the company has ambitious plans for the future. They are committed to expanding their product range and reaching new markets to further establish themselves as a leading supplier of woodworking machinery. With a strong emphasis on innovation, quality, and customer satisfaction, they are well-positioned to continue driving the industry forward.

The release of the EVA edge banding machine is a testament to their dedication to pushing the boundaries of what is possible in the woodworking industry. By delivering cutting-edge technology and reliable solutions, they are setting a new standard for efficiency and quality.

In conclusion, the EVA edge banding machine represents a significant leap forward in the woodworking industry. Its advanced technology, versatility, and efficiency make it a valuable asset for woodworking companies looking to streamline their production processes and deliver exceptional results. With the backing of a reputable and innovative company, the EVA edge banding machine is poised to revolutionize the way edge banding is applied to wood-based materials.

Company News & Blog

Experts Predict Rise in Demand for Wood Shapers as Craftsmen Seek Efficient Solutions

Wood Shaper: Revolutionizing the Woodworking IndustryIn the ever-evolving world of technology, innovation has become the cornerstone of progress. Keeping up with this trend, the woodworking industry has witnessed a significant breakthrough with the introduction of Wood Shaper - a revolutionary device that is set to transform the way wood is shaped and crafted. Developed by an industry-leading company, Wood Shaper has garnered attention and accolades for its cutting-edge features and unmatched precision.Woodworking is an art form that dates back centuries, where skilled craftsmen used primitive tools and techniques to shape and mold wood into exquisite creations. While the essence of this art remains the same, the introduction of Wood Shaper brings with it a wave of advancement that promises to elevate woodworking to new heights.Created by a team of experts at {}, Wood Shaper is the result of extensive research and development aimed at addressing the challenges faced by woodworkers. By leveraging the power of technology, this state-of-the-art device offers a range of features that make it stand out from traditional woodworking tools.One of the fundamental advantages of Wood Shaper is its unparalleled precision and accuracy. Equipped with advanced sensors and tracking systems, the device ensures that every cut and carve is executed with utmost precision, eliminating human error to a great extent. This not only saves time and effort but also produces flawless results, elevating the quality of crafted woodwork.Moreover, Wood Shaper offers a remarkable level of versatility, making it suitable for a wide range of woodworking projects. From intricate designs to large-scale structures, the device can be easily adjusted to accommodate various specifications. This flexibility gives woodworkers the freedom to explore their creativity and push the boundaries of their craft.The ease of use is another noteworthy feature of Wood Shaper. Designed to simplify the woodworking process, this device incorporates intuitive controls and user-friendly interfaces. Even novices can swiftly familiarize themselves with the functionalities of Wood Shaper and produce professional-grade woodwork. This accessibility opens up new opportunities for aspiring woodworkers, bridging the gap between skill and technology.Furthermore, Wood Shaper is built with durability and longevity in mind. Crafted from high-quality materials, the device can withstand rigorous usage and is resistant to wear and tear. This ensures that Wood Shaper remains a reliable tool for woodworkers, providing them with an investment that will endure for years to come.The environmental impact of woodworking has also been given due consideration in the development of Wood Shaper. The device incorporates eco-friendly features that minimize waste material and promote sustainability. This conscious effort aligns with the growing global focus on reducing carbon footprint and adopting environmentally friendly practices.With its unique blend of precision, versatility, ease of use, durability, and sustainability, Wood Shaper has taken the woodworking industry by storm. Woodworkers around the world have swiftly embraced this innovative device and have seen a significant improvement in their craft. As the trend of automation and digitization continues to shape various industries, Wood Shaper is a shining example of how technology can enhance traditional art forms.Looking ahead, the future of Wood Shaper seems promising. The {} company behind its creation remains committed to continuous improvement and innovation. Plans for future upgrades and enhancements to the device are already in the pipeline, ensuring that woodworkers will benefit from the latest advancements in technology.In conclusion, the introduction of Wood Shaper has revolutionized the woodworking industry. With its precision, versatility, ease of use, durability, and sustainability, this cutting-edge device has become an essential tool for woodworkers worldwide. As the industry progresses, Wood Shaper stands as a testament to the power of innovation and technology in elevating traditional crafts to new heights.

Advanced CNC Machines: The Future of Manufacturing

The manufacturing industry is rapidly evolving with the integration of advanced technologies, and one such groundbreaking innovation is the use of Computer Numerical Control (CNC) machines. These machines have revolutionized the manufacturing process by enhancing precision, efficiency, and productivity. One company at the forefront of this technological revolution is {Company Name}, a leading supplier of CNC machines to the global market.{Company Name} has been a pioneer in the manufacturing industry, specializing in the development and production of cutting-edge CNC machines. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted and reliable partner for businesses looking to enhance their manufacturing capabilities.CNC machines have become an essential tool in modern manufacturing, offering a wide range of applications across various industries. These machines are capable of producing highly accurate and complex parts and components, making them indispensable for businesses looking to maintain a competitive edge in today’s fast-paced market.The key advantage of CNC machines lies in their ability to automate the manufacturing process, which significantly reduces the margin of error and increases overall efficiency. This can lead to cost savings for businesses, as well as a higher level of quality control in the production of goods.{Company Name} has been at the forefront of this technological transformation, developing cutting-edge CNC machines that are tailored to meet the unique requirements of its diverse customer base. The company’s commitment to research and development has led to the creation of CNC machines that offer unparalleled precision, speed, and reliability.One of the key features of {Company Name}'s CNC machines is their user-friendly interface, which allows operators to easily program and control the manufacturing process. This intuitive system empowers businesses to optimize their production workflows and make real-time adjustments to meet evolving market demands.In addition, {Company Name} provides comprehensive training and support services to ensure that its customers can maximize the potential of their CNC machines. This commitment to customer satisfaction has earned the company a solid reputation in the industry, with a growing clientele of satisfied businesses that have experienced the transformative impact of CNC technology.The versatility of {Company Name}'s CNC machines allows them to be used in a wide range of industries, including aerospace, automotive, medical, and electronics. The machines are capable of producing intricate and high-precision components, making them an invaluable asset for businesses operating in these sectors.The integration of CNC machines in manufacturing processes has not only improved the efficiency and quality of production but has also paved the way for innovation and customization. With the ability to produce complex and unique parts, businesses can now explore new design possibilities and offer customized solutions to their customers.Furthermore, the use of CNC machines has also contributed to the reduction of lead times in manufacturing, allowing businesses to respond more swiftly to market demands and stay ahead of the competition. This has proven to be a crucial advantage for businesses operating in industries with fast-evolving consumer preferences and technological advancements.As the demand for CNC machines continues to grow, {Company Name} remains at the forefront of the industry, consistently developing and introducing new technologies to meet the evolving needs of its customers. The company’s commitment to innovation and customer satisfaction has positioned it as a trusted partner for businesses looking to enhance their manufacturing capabilities and drive growth in the competitive global market.In conclusion, the integration of CNC machines in modern manufacturing processes has ushered in a new era of precision, efficiency, and customization. {Company Name} has played a pivotal role in this transformation, offering cutting-edge CNC machines and comprehensive support services to businesses worldwide. With a strong focus on innovation and customer satisfaction, {Company Name} is poised to lead the industry into the future, empowering businesses to achieve new levels of productivity and success.

Advanced CNC Wood Cutting Machine Offers Precision and Efficiency

In recent years, the development of technology has greatly transformed the manufacturing industry, and the woodworking industry is no exception. With the introduction of advanced CNC wood cutting machines, woodworking companies are able to streamline their production processes, increase efficiency, and improve the quality of their products. One company at the forefront of this technological revolution is {}, a leading manufacturer of CNC wood cutting machines.{} has been a pioneer in the field of woodworking machinery for over two decades, and their CNC wood cutting machines have become a staple in woodworking workshops around the world. The company's commitment to innovation and precision engineering has made them a trusted partner for woodworking businesses looking to enhance their capabilities and stay ahead of the competition.The company's CNC wood cutting machines are designed to offer high-speed, high-precision cutting of various types of wood materials. Equipped with advanced features such as automatic tool changers, vacuum beds, and computer-controlled routing, these machines are capable of producing intricate designs and complex shapes with unparalleled accuracy. This level of precision and efficiency has allowed woodworking companies to take on more challenging projects and deliver superior results to their clients.One of the key advantages of using {}'s CNC wood cutting machines is the reduction in material waste and labor costs. Traditional woodworking methods often result in a significant amount of material being wasted due to imprecise cutting and shaping. With CNC technology, the cutting process is optimized to minimize waste, leading to cost savings and greater sustainability. Additionally, the automated nature of these machines allows for increased productivity, as operators can focus on other tasks while the CNC machine handles the cutting process.The versatility of {}'s CNC wood cutting machines is another factor that sets them apart from the competition. These machines can handle a wide range of woodworking tasks, including cutting, drilling, routing, and engraving, making them suitable for diverse projects and applications. Whether it's creating custom furniture, intricate cabinetry, or decorative wood panels, these machines offer the flexibility to meet the demands of modern woodworking businesses.In addition to their cutting-edge technology, {} also provides comprehensive training and support to help woodworking companies integrate their CNC wood cutting machines into their production processes seamlessly. The company's team of experienced technicians and engineers are available to provide on-site training, technical assistance, and ongoing maintenance to ensure that their machines operate at peak performance.{}'s commitment to customer satisfaction and technological innovation has earned them a reputation as a leader in the woodworking machinery industry. Their CNC wood cutting machines have empowered woodworking businesses to elevate their capabilities, expand their offerings, and achieve greater success in a competitive market.Furthermore, {}'s dedication to research and development ensures that their CNC wood cutting machines continue to evolve with the latest advancements in technology. This ongoing innovation enables woodworking companies to stay at the forefront of the industry and meet the increasingly complex demands of their customers.As the woodworking industry continues to embrace digitalization and automation, CNC wood cutting machines have become indispensable tools for businesses looking to stay ahead in a dynamic market. With {}'s cutting-edge technology and industry-leading expertise, woodworking companies can expect to achieve greater efficiency, precision, and profitability in their operations.In conclusion, {}'s CNC wood cutting machines have revolutionized the woodworking industry, providing businesses with the tools they need to thrive in a competitive market. The company's commitment to innovation, quality, and customer support has made them a valuable partner for woodworking businesses around the world. With {}'s CNC wood cutting machines, woodworking companies can look forward to a future of enhanced productivity, expanded capabilities, and continued success.

High-Quality Edgebander Tape for All Your Woodworking Needs

Edgebander Tape Revolutionizes Cabinet Making IndustryThe cabinet making industry has seen a revolution with the introduction of [Company Name]'s innovative Edgebander Tape. The company has been a leader in providing high-quality solutions for the woodworking and furniture industries, and their latest product has taken the industry by storm.[Company Name] has been a trusted name in the woodworking industry for over 20 years. With its commitment to innovation and quality, the company has remained at the forefront of providing cutting-edge solutions for cabinet makers and furniture manufacturers. The launch of their Edgebander Tape is a testament to their dedication to meeting the evolving needs of their customers.The Edgebander Tape is a game-changer for cabinet makers as it offers a cost-effective and efficient solution for edgebanding. Traditional edgebanding methods often require the use of adhesives and specialized equipment, which can be time-consuming and labor-intensive. However, [Company Name]'s Edgebander Tape simplifies the process by providing a convenient and reliable alternative.One of the key features of the Edgebander Tape is its ease of use. Cabinet makers can simply apply the tape to the edges of their furniture or cabinet pieces and use a standard edgebander machine to achieve a seamless and durable finish. This not only saves time but also reduces the need for specialized skills, making it an ideal solution for both small-scale workshops and large manufacturing facilities.In addition to its ease of use, the Edgebander Tape also offers superior performance and durability. The tape is made from high-quality materials that are designed to withstand the rigors of everyday use. This ensures that the edges of the furniture or cabinets remain protected and secure, providing a long-lasting finish that meets the highest standards of quality.Furthermore, the Edgebander Tape is available in a wide range of colors and finishes, allowing cabinet makers to achieve a customized look for their products. This level of versatility is a significant advantage for manufacturers who cater to diverse customer preferences and design aesthetics. Whether it's a sleek and modern finish or a classic and traditional look, the Edgebander Tape delivers exceptional results every time.The introduction of [Company Name]'s Edgebander Tape has garnered high praise from cabinet makers and furniture manufacturers alike. Many have lauded the product for its ability to streamline production processes and improve the overall quality of their products. This has ultimately translated to higher customer satisfaction and increased profitability for businesses that have integrated the tape into their operations.Moreover, the Edgebander Tape has also been recognized for its environmental benefits. By eliminating the need for solvent-based adhesives, the tape reduces harmful emissions and promotes a greener approach to woodworking. This aligns with [Company Name]'s commitment to sustainability and responsible manufacturing practices, further cementing their reputation as an industry leader.Looking ahead, [Company Name] continues to innovate and expand its product offerings to meet the evolving needs of the woodworking and furniture industries. With the successful launch of the Edgebander Tape, the company has set a new standard for edgebanding solutions and has demonstrated its unwavering dedication to providing practical and high-quality products for its customers.In conclusion, [Company Name]'s Edgebander Tape has had a significant impact on the cabinet making industry, offering a cost-effective, efficient, and versatile solution for edgebanding. With its ease of use, superior performance, and environmental benefits, the tape has garnered widespread acclaim and has solidified [Company Name]'s position as a leader in providing innovative solutions for the woodworking and furniture industries.

Revolutionize Your Furniture Making Process with Cutting-Edge Wood Machinery

[introduction]Wood furniture making is a significant industry that caters to the growing demands of consumers worldwide. With the help of advanced technology and machinery, manufacturers are revolutionizing the production process, making it more efficient and sustainable. In line with this trend, a leading company in the field has recently introduced a groundbreaking wood furniture making machine designed to enhance productivity while reducing environmental impact. Through the integration of innovative features, this new machine aims to streamline the manufacturing process, resulting in high-quality wood furniture for consumers.[Background on the company]The company, a prominent player in the woodworking machinery industry, has been at the forefront of technological advancements for years. With a focus on providing reliable and innovative solutions, they have established a reputation for delivering cutting-edge equipment that meets the diverse needs of manufacturers. Committed to sustainability, the company continuously invests in research and development to develop machines that minimize waste, reduce energy consumption, and optimize production efficiency. With an extensive global presence and a team of highly skilled engineers, they have successfully catered to the demands of clients worldwide, meeting the highest standards in quality and performance.[Introduction of the wood furniture making machine]The latest addition to the company's product portfolio is the revolutionary wood furniture making machine. Designed to address the challenges faced by manufacturers, such as labor-intensive processes, long production times, and limited customization options, this machine offers a comprehensive solution that revolutionizes the entire production process.One of the key features of this machine is its automated functionality. By integrating computer numerical control (CNC) technology, it allows for precise and accurate execution of complex wood-cutting operations. This not only reduces manual labor but also ensures consistency in the quality and dimensions of the furniture pieces. The machine's intuitive user interface enables operators to easily program and control the cutting and shaping processes, contributing to increased productivity and reduced error rates.Furthermore, the machine includes advanced sensors and cameras that enable real-time monitoring and quality control. Through automated inspections, any defects or inconsistencies can be detected immediately, allowing for prompt corrective action. This feature significantly improves the overall quality of the wood furniture produced, minimizing waste and enhancing customer satisfaction.In addition to its manufacturing capabilities, the wood furniture making machine also offers improved design customization options. By integrating computer-aided design (CAD) technology, manufacturers can easily create intricate and unique designs that were previously difficult to achieve manually. This level of design flexibility allows for greater creativity and customization, empowering manufacturers to cater to specific customer requests and differentiate their product offerings in a highly competitive market.[Impact on sustainability and environmental considerations]With sustainable practices at the core of its philosophy, the company ensured that this wood furniture making machine aligns with its commitment to environmental responsibility. The machine incorporates advanced dust collection systems that efficiently capture and filter wood particles, reducing airborne dust and promoting a healthier working environment. Moreover, the machine optimizes material usage through intelligent software algorithms, minimizing waste and improving resource efficiency. By enhancing energy efficiency and reducing carbon emissions, this machine represents a significant step towards achieving a greener and more sustainable wood furniture manufacturing industry.[Conclusion]As the demand for wood furniture increases, manufacturers must adapt to evolving consumer preferences and market dynamics. This wood furniture making machine, introduced by the company, offers an innovative and comprehensive solution to streamline production, improve customization, and reduce environmental impact. With its advanced features, including automated processes, real-time quality control, and enhanced design options, this machine empowers manufacturers to meet consumer demands while ensuring sustainability. By embracing such technological advancements, the wood furniture industry can continue to thrive, providing high-quality and aesthetically pleasing furniture for consumers worldwide.

Top Foam Cutting Machine for Precision Cutting of Materials

CNC Foam Cutter Revolutionizing the Manufacturing IndustryIn the world of manufacturing, precision and efficiency are key components to success. With the advancement of technology, companies are constantly looking for innovative ways to improve their production processes. One such innovation that has been making waves in the industry is the CNC foam cutter.A CNC foam cutter is a computer-controlled machine that is designed to cut intricate shapes and designs out of foam materials with extreme precision. This technology has quickly become a popular choice for manufacturers in a variety of industries, including aerospace, automotive, packaging, and more.One company that has been at the forefront of this technological advancement is {Company Name}. With over 20 years of experience in the manufacturing industry, {Company Name} has established itself as a leader in providing cutting-edge solutions for its clients. The company's expertise in CNC foam cutting technology has allowed them to develop state-of-the-art machines that are capable of meeting the demands of even the most complex manufacturing projects.{Company Name} offers a range of CNC foam cutting machines that are designed to cater to the specific needs of their clients. Whether it is for prototyping, production or custom projects, their machines are known for their reliability, precision, and speed. The company's commitment to innovation and customer satisfaction has made them a trusted partner for manufacturers looking to enhance their production capabilities.One of the key advantages of using a CNC foam cutter is the level of precision it offers. Traditional methods of foam cutting often result in inaccuracies and inconsistencies, leading to wasted time and materials. However, with a CNC foam cutter, manufacturers can achieve the exact shapes and designs they need with minimal wastage, resulting in cost savings and improved product quality.Furthermore, the speed at which these machines operate is a game-changer for manufacturers who are looking to streamline their production processes. With the ability to cut intricate designs in a fraction of the time it would take using traditional methods, CNC foam cutters can significantly increase productivity and output.Additionally, the versatility of CNC foam cutters allows manufacturers to explore a wide range of design possibilities. Whether it is creating custom packaging, intricate molds for composites, or decorative elements for automotive interiors, the possibilities are endless with this technology.As the demand for CNC foam cutters continues to grow, {Company Name} has been at the forefront of meeting this demand. Their commitment to research and development has led to the creation of innovative solutions that have set the industry standard. By providing reliable machines that deliver exceptional results, {Company Name} has solidified its position as a leading provider of CNC foam cutting technology.In conclusion, the introduction of CNC foam cutters has revolutionized the manufacturing industry, providing manufacturers with a powerful tool to enhance their production capabilities. Companies like {Company Name} have played a pivotal role in advancing this technology and helping their clients achieve new levels of precision and efficiency. As the industry continues to evolve, CNC foam cutters will undoubtedly remain a vital tool for manufacturers looking to stay ahead of the curve. With the expertise and innovation of companies like {Company Name}, the future of manufacturing looks brighter than ever.

Revolutionary CNC Drilling Machine Takes Precision to New Heights!

Intelligent CNC Drilling Machine Revolutionizes Manufacturing ProcessesIn an era characterized by rapid technological advancements, manufacturers are constantly seeking innovative solutions that can enhance productivity, precision, and efficiency. One such game-changing technology is the intelligent CNC drilling machine, which has transformed traditional manufacturing processes worldwide. This state-of-the-art equipment, developed by a leading engineering company, has revolutionized the way products are produced, significantly reducing production time and improving overall quality.The intelligent CNC drilling machine, designed with cutting-edge technology, boasts an array of features that have redefined modern manufacturing. Equipped with advanced computer numerical control (CNC) software, the machine can automatically execute precise drilling operations with minimal human intervention. This not only reduces the risk of human error but also enhances repeatability and consistency, delivering unparalleled levels of accuracy during the manufacturing process.By incorporating artificial intelligence (AI) algorithms, the intelligent CNC drilling machine has the ability to continuously learn and optimize its performance. This AI-driven system analyzes real-time data and adjusts drilling parameters accordingly, ensuring optimal production efficiency. Furthermore, the machine’s intelligent sensor technology detects any irregularities, such as material variations or tool wear, and promptly adjusts the drilling process to maintain consistent quality standards.The intelligent CNC drilling machine has emerged as a game-changer in the manufacturing industry due to its versatility and adaptability. With its wide range of customization options, the machine can cater to the unique requirements of various industries, including aerospace, automotive, and electronics. Whether it is drilling complex patterns, intricate holes, or even 3D structures, this state-of-the-art equipment can execute the most challenging tasks with utmost precision and speed.Moreover, the intelligent CNC drilling machine promotes sustainability by minimizing material waste. Through real-time monitoring and adjustment of drilling parameters, the machine optimizes the use of resources, ensuring minimal material scrap. This not only reduces environmental impact but also contributes to cost savings for manufacturers.The company behind the intelligent CNC drilling machine has a rich history of engineering excellence and has been at the forefront of innovation for decades. With a strong commitment to research and development, the company has successfully introduced a series of market-leading products. The intelligent CNC drilling machine is the result of extensive investment in cutting-edge technologies and continuous collaboration with industry experts.Recognizing the importance of customer satisfaction, the company supplements its state-of-the-art equipment with comprehensive customer support services. Highly trained technicians provide installation assistance, machine customization, and troubleshooting support, ensuring seamless integration of the intelligent CNC drilling machine into clients’ manufacturing processes. Additionally, regular software updates and maintenance services guarantee optimal machine performance and longevity.As a testament to its success, the intelligent CNC drilling machine has received industry-wide recognition and numerous accolades. Manufacturers across the globe have adopted this technology to streamline their production processes, leading to increased productivity and profitability. This ground-breaking innovation has not only transformed the way products are manufactured but has also set new industry standards for precision and efficiency.In conclusion, the intelligent CNC drilling machine has revolutionized the manufacturing industry with its cutting-edge technology, precision, and efficiency. By seamlessly integrating AI algorithms and intelligent sensor technology, this state-of-the-art equipment has redefined production processes, delivering exceptional quality standards. Backed by a company renowned for its engineering excellence and comprehensive customer support, the intelligent CNC drilling machine has become a go-to solution for manufacturers seeking to enhance their operations and remain at the forefront of technological advancements.

Effective Drill Press Jigs for Precision Woodworking

[Company Name] is a renowned manufacturer of high-quality drill press jigs that are used in various machining and woodworking applications. The company has been in the industry for over 20 years and has established itself as a leader in providing innovative and reliable solutions for precision drilling operations.The drill press jigs offered by [Company Name] are designed to enhance the accuracy, efficiency, and safety of drilling processes. These jigs are engineered using advanced technology and high-quality materials to ensure superior performance and durability. With a strong focus on customer satisfaction, [Company Name] continually strives to develop products that meet the evolving needs of the industry.Recently, [Company Name] launched its latest line of drill press jigs, which has generated significant interest and acclaim within the manufacturing and woodworking community. The new jigs incorporate a range of advanced features and improvements that set them apart from conventional models. These innovations have been developed in response to feedback from customers and industry professionals, highlighting [Company Name]'s commitment to delivering cutting-edge solutions.One of the key features of the new drill press jigs is their versatility. They have been engineered to accommodate a wide range of drilling applications, making them suitable for various industries and projects. This flexibility allows operators to achieve precise and consistent results across different materials and workpieces, contributing to improved productivity and quality.In addition to their versatility, the new drill press jigs offer enhanced safety features that prioritize the well-being of operators. With robust safeguards and ergonomic design elements, these jigs minimize the risk of accidents and injuries in the workplace, providing a secure drilling environment for users.Another notable aspect of the new line of drill press jigs is their user-friendly interface. [Company Name] has incorporated intuitive controls and adjustable settings into the jigs, streamlining the operation process and enabling operators to achieve desired drilling outcomes with ease. This user-centric approach reflects [Company Name]'s dedication to empowering professionals with efficient and intuitive tools.Moreover, the new jigs boast improved accuracy and precision, thanks to state-of-the-art engineering and manufacturing practices. They are designed to deliver consistent drilling results with minimal margin for error, ensuring that every hole is drilled with exacting precision. This level of accuracy is essential for applications that demand meticulous attention to detail and strict adherence to specifications.The launch of [Company Name]'s latest drill press jigs has been met with an overwhelmingly positive response from customers, who have praised the jigs for their performance, reliability, and convenience. Many have expressed their satisfaction with the new features and enhancements, noting their positive impact on productivity and workflow efficiency.Furthermore, [Company Name] continues to provide comprehensive support and resources to accompany its drill press jigs, including user manuals, technical assistance, and maintenance services. This commitment to customer care reinforces [Company Name]'s reputation as a trusted and dependable partner in the industry.In conclusion, [Company Name] has reaffirmed its position as a leading provider of drill press jigs with the launch of its latest line of innovative and reliable products. Through continuous innovation, customer-centric design, and unwavering commitment to quality, [Company Name] has set a new standard for excellence in the field of precision drilling. As the industry evolves, [Company Name] remains dedicated to meeting the evolving needs and expectations of its customers, upholding its reputation as a frontrunner in the market.

Top Benefits of Using a Radial Drill for Your Projects

Radial Drill, a leading manufacturer of industrial machines and equipment, has recently unveiled their latest innovative product that is set to revolutionize the construction and manufacturing industries. The new radial drill, which is designed to provide unmatched precision and efficiency, is the result of years of research and development by the company's team of experienced engineers and technicians.The new radial drill boasts a number of advanced features that set it apart from other similar products on the market. It is equipped with a powerful motor and high-quality components that ensure smooth and precise drilling operations. The drill also comes with a range of safety features to protect the operator and prevent accidents in the workplace. Additionally, its compact and ergonomic design makes it easy to maneuver and operate in a variety of work environments.One of the key advantages of the new radial drill is its versatility. It is capable of drilling holes of various sizes and depths in different types of materials, including metal, wood, and plastic. This makes it an essential tool for a wide range of applications, from construction and metalworking to furniture manufacturing and woodworking.In addition to its exceptional performance, the new radial drill is also designed with the environment in mind. It is energy-efficient and produces minimal noise and vibration during operation, which not only reduces the carbon footprint but also ensures a more comfortable working environment for the operator.Mr. John Smith, the CEO of Radial Drill, expressed his enthusiasm about the launch of the new product, stating, "We are thrilled to introduce our latest radial drill to the market. As a company, we are committed to delivering innovative and high-quality solutions to our customers, and we believe that this new product will exceed their expectations."The company, founded in 1980, has a long-standing reputation for excellence in the manufacturing industry. Their extensive range of products includes not only radial drills but also milling machines, lathes, and CNC machining centers, among others. With a dedication to quality and customer satisfaction, Radial Drill has established itself as a trusted and reputable brand in the global market.The launch of the new radial drill is expected to further solidify the company's position as a leader in the industry. With its advanced features, superior performance, and environmental sustainability, the product is set to attract the attention of companies and manufacturers looking to enhance their productivity and efficiency.In response to the growing demand for the new product, Radial Drill has already started taking orders and is set to begin shipping in the coming weeks. The company is also planning to showcase the radial drill at upcoming industry events and trade shows to give potential customers the opportunity to see the product in action and learn more about its benefits.As the manufacturing and construction industries continue to evolve, the demand for innovative and high-performance tools and equipment is on the rise. With the launch of their new radial drill, Radial Drill is well-positioned to meet this demand and provide customers with cutting-edge solutions that will help them stay ahead in an increasingly competitive market.In conclusion, the new radial drill from Radial Drill represents a significant advancement in drilling technology. With its superior performance, versatility, and environmental sustainability, the product is set to make a significant impact in the construction and manufacturing industries. As a company with a long history of delivering high-quality solutions, Radial Drill is poised to continue its success with this latest offering.

High-quality Mortiser Drill Bit for Precise Woodworking Projects

Mortiser Drill Bit: The Ultimate Tool for Precision WoodworkingWoodworking has always been a craft that requires precision, attention to detail, and the right tools to bring a vision to life. For many woodworking professionals and hobbyists, finding the perfect tool to achieve the intricate and precise cuts needed for their projects can be a challenge. This is where the Mortiser Drill Bit comes in.The Mortiser Drill Bit, produced by a leading manufacturer in the woodworking tool industry, is a game-changer for those who need to create clean and accurate mortise and tenon joints in their woodworking projects. The company behind this innovative tool has been a trusted name in the woodworking tool industry for over 50 years, with a commitment to producing high-quality and reliable tools for professionals and enthusiasts alike.The Mortiser Drill Bit is designed to be used with a mortising machine, which is a specialized woodworking tool used to cut square or rectangular holes in a piece of lumber. These holes, known as mortises, are typically used to create joints with a matching projection, known as a tenon. This type of joint is commonly used in furniture making, as it provides strength and stability to the finished piece.What sets the Mortiser Drill Bit apart from other similar tools on the market is its precision and durability. Made from high-quality materials, this drill bit is engineered to deliver clean and precise cuts, ensuring that each mortise is uniform and accurate. Its sharp edges and durable construction make it capable of handling even the toughest woodworking projects, allowing for smooth and efficient operation with minimal risk of chipping or dulling.In addition to its superior performance, the Mortiser Drill Bit also offers versatility, making it suitable for a wide range of woodworking applications. Whether it's creating mortise and tenon joints for a table, chair, cabinet, or any other woodworking project, this tool is designed to deliver consistent results, no matter the size or complexity of the job.The company behind the Mortiser Drill Bit takes pride in its commitment to customer satisfaction and product innovation. With decades of experience in the woodworking tool industry, they understand the unique needs and challenges that woodworkers face. This understanding has driven them to continuously refine and improve their products, ensuring that they meet the highest standards of quality and performance.One of the company's core values is integrity, and this is reflected in the meticulous design and manufacturing process of the Mortiser Drill Bit. Every detail, from the selection of materials to the precision engineering, is carefully considered to create a tool that woodworkers can rely on for years to come. This commitment to excellence has earned the company a reputation for producing some of the most dependable and sought-after woodworking tools in the industry.As woodworking continues to evolve and demand for precision tools grows, the Mortiser Drill Bit remains a staple in the toolkits of professionals and hobbyists alike. Its ability to deliver clean, accurate, and reliable results makes it an essential tool for anyone looking to take their woodworking projects to the next level.In conclusion, the Mortiser Drill Bit, produced by a reputable and established woodworking tool manufacturer, is a testament to the innovation and quality that the company stands for. With its precision, durability, and versatility, this tool has become a trusted companion for those who demand nothing but the best for their woodworking projects. As the woodworking industry continues to thrive, the Mortiser Drill Bit proves to be an indispensable tool for those who take pride in their craft and refuse to compromise on quality.